Basic MIG theory:

1. MIG (or GMAW) is based on a constant voltage (that's the "heat" dial) and a consumable wire electrode (wire feed dial - if fancy, it's in inches per minute - this controls both wire feed and current (amperage)).

2. The shielding gas only performs a shielding and cleaning function - this is fundamentally different from say TIG welding. It keeps the molten weld pool in a different atmosphere while the weld is forming and during initial solidification. Set it and forget it.

3. Material thickness controls amperage for all weld processes (that involve electricity) and for GMAW, 1 amp per thou of thickness is a general rule for steel.

4. Wire is consumed at a rate that is proportional to the wire size, amps and the voltage applied. For example, if your welding sheet metal, I'll assume you're using either 0.030" or 0.035" wire. The guidelines indicate that for 0.030" wire, the wire feed rate should be 2" per minute per amp of current. So the "heat" dial sets the voltage (think depth of penetration - voltage is a force) and the wire feed controls the rate of wire consumption (current or rate). That's how they compute the charts on the inside of your machine that tell you the settings for a given gauge by a wire diameter.

5. The length of the arc that you maintain controls the current...this gets a little tricky, so let me try to explain it this way. All of what I've said so far makes sense (voltage, wire feed, amps) if and only if the length of the arc is a constant. If you need to "cool off" your weld, lengthen your arc or to heat it up, tighten the distance. One of the mistakes I see with beginners is holding the MIG gun so that they can see the weld and therefore holding the arc a long way off the weld. Push that sucker down into the puddle. This is what's called "Stick Out" which refers to the distance from the electrode being consumed to the weld puddle. A normal arc length is around 1/4".

For practice, I suggest you do the following:

1. Grab some scrap material (1/8" flat bar) and set the voltage and wire feed based on the guidelines with your machine (I'm assuming you're gas is set properly). Then hold the gun with

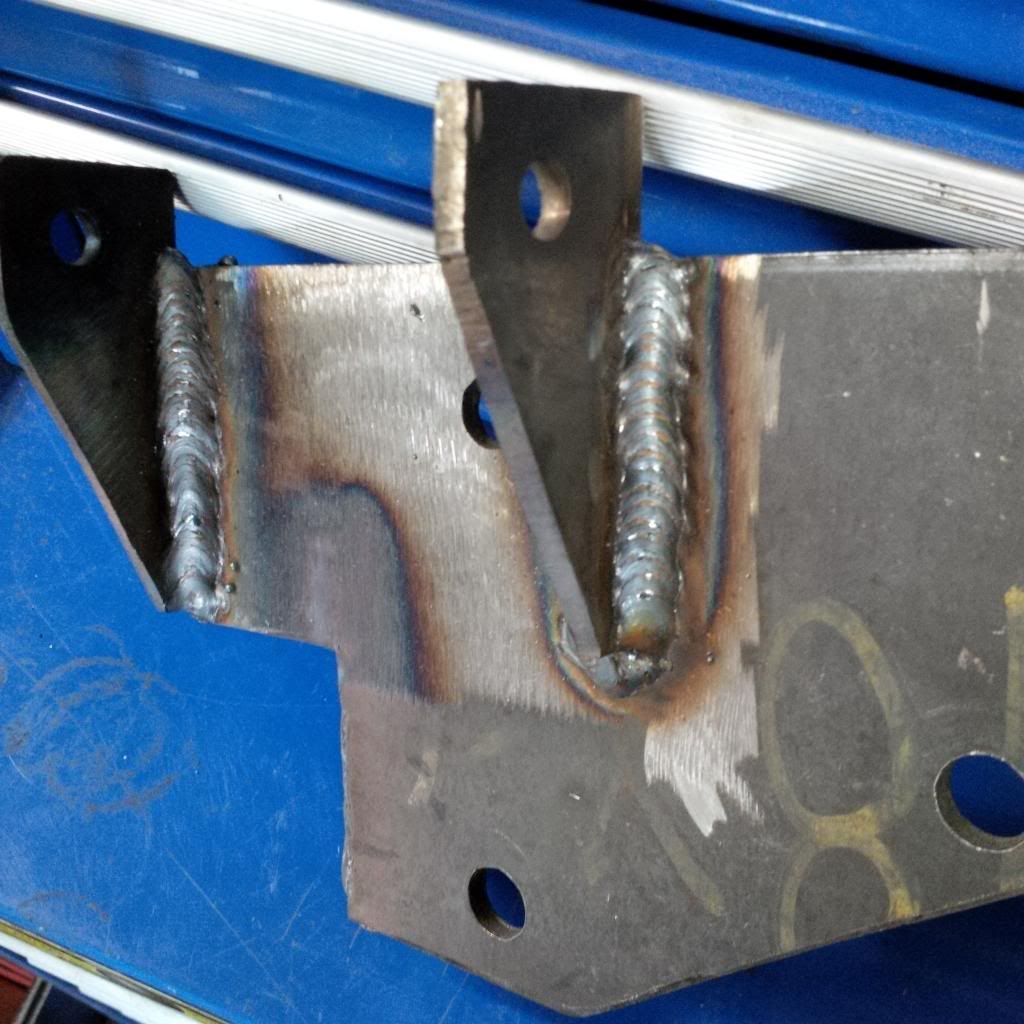

both hands and set a distance 1/4" off the target (get a feel for that distance by setting your tip on a few pieces of scrap that make up that height). Now move off your support, and with your helmet down, pull the trigger and move (push/pull...I don't care) and see what happens when you hold the gun straight down. Now you'll need a bit of angle, so try 10-15° and go again. Adjust only the wire feed knob until you get the wire melting but not bumping into the puddle and not melting back into the tip. It should sound like frying bacon...now you're cookin (sorry - couldn't resist).

2. Go weld - you're now a pro.

Craig

http://www.millerwelds.com/pdf/mig_handbook.pdf