Ahhh, okay. So something about the 740 setup required the RSR. I'm more than happy to ditch it...the less stuff in the engine bay the better. Glad to ditch the ballasts too as those things are UGLY.

Yup, I was starting to think about pulling the trigger last night!! It was tempting, but my battery needs a charge, and I didn't want to do it without Craig there, considering all the help he's given me. And also, in case something is awry and starts on fire....

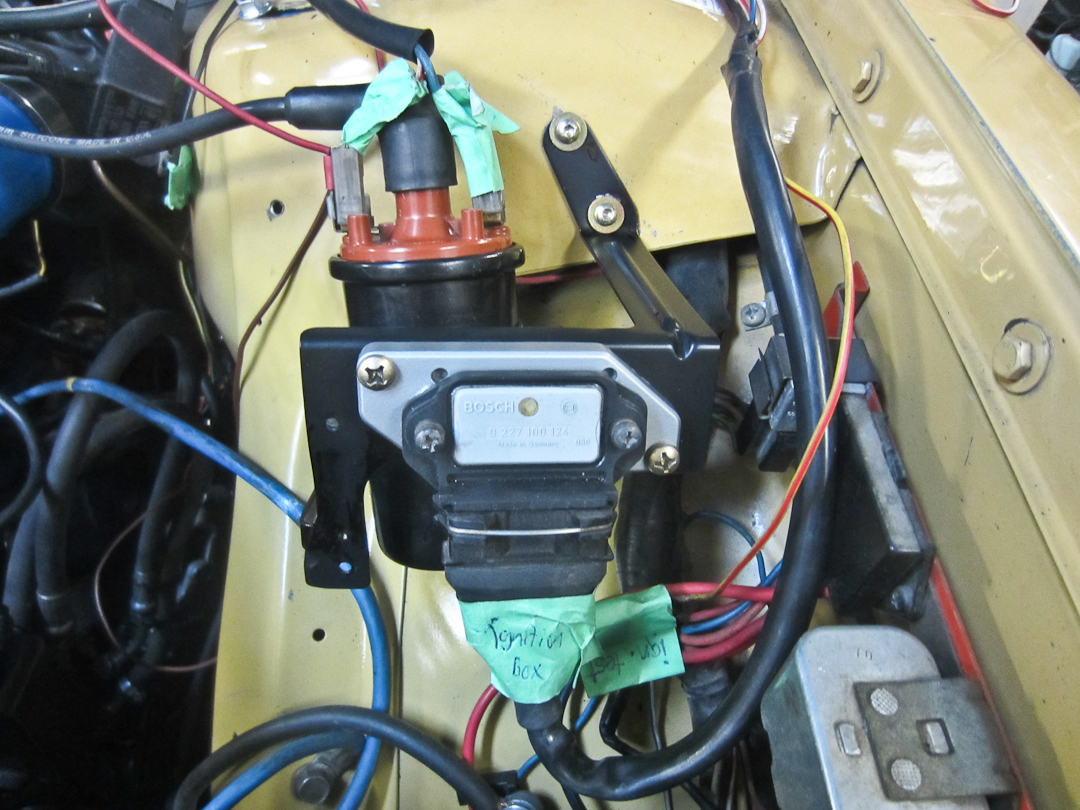

Hahah, and yes, the engine bay is still rather clean. I was a little annoyed when I pulled the power stage wire under the strut tower and it was all dirty. GAH! My brand new clean harness is ruined! I still wish it was more tidy, especially all the extra wire that's there on the chassis side that doesn't need to be. Guess that's for down the road.

Very excited though. Didn't leave the garage until 11:30 and didn't fall asleep until 1:00. It feels good to work on this again. I'm just trying not to get overwhelmed with all the little things that need finishing. So here's the list to get the car driveable:

-connect alternator and oil pressure sender

-test harness to ensure continuity/everything works

-fix one injector connection (only fault I've found with the harness so far)

-turn key

-solve/build air box (Craig, did we ever consider cutting the 740 box down in height to make it fit?)

-mount LH computer on kick panel

-finish wiring for R-Sport cluster

-solve mounting for boost gauge (really want to build/buy 3 panel cluster for top of dash, but may have to settle for mounting in air vent or a-pillar for now)

Edit: here's what Dave had to say about the ballast.

"Hi Greg,

Yes. I decided to go with a 240 version, which never had an RSR. I've never quite figured out what is so important about it if they never designed it into the 240, since NA 700/900's got them with LH 2.4. Mostly I have viewed it as a future failure point anyway.

I had a discussion with some others about a ballast resistor and came to the conclusion that the extra wiring task involved was not worth the effort. I've been told that long ago a low impedence injector was preferred for high flow applications, but with new technology it's no longer an issue. However, if someone wanted such a thing bad enough, we would consider making it for an extra cost.

The ballast resistor has one wire that is linked to the RSR, so they are connected, but not interdependent. Examples seen here in the B230FT LH 2.2 and B230F LH 2.4 diagrams, which have the RSR:

http://www.volvowiringdiagrams.com/volv ... agrams.pdfDave"