Moving on to the drivers side seemed easy enough...just get the pedal set clearance I need then fabricate a box to hold all the floor mount pedal goodness and be done with it. Not so fast Sparky. Staring at it for an hour yielded a few conclusions. First up, the placement of the engine shouldn't matter, or so I thought. I was more worried about the frame rail and it's relationship to the cross member. For those who have no idea why I'm rambling, you've never driven a 122. The accelerator pedal is painfully close to the transmission tunnel.

To fit the engine in the car, the transmission tunnel needs be be a little larger all over to fit the bell housing. But that growth should all by in the forward sloping area of the tunnel, not around the pedal area (which is low down). I had pulled the entire transmission tunnel from firewall back from a 240 - it's far too large to fit in a 122. I will need to use the back section to fit the transmission shifter, but the front is massive and I can't use it.

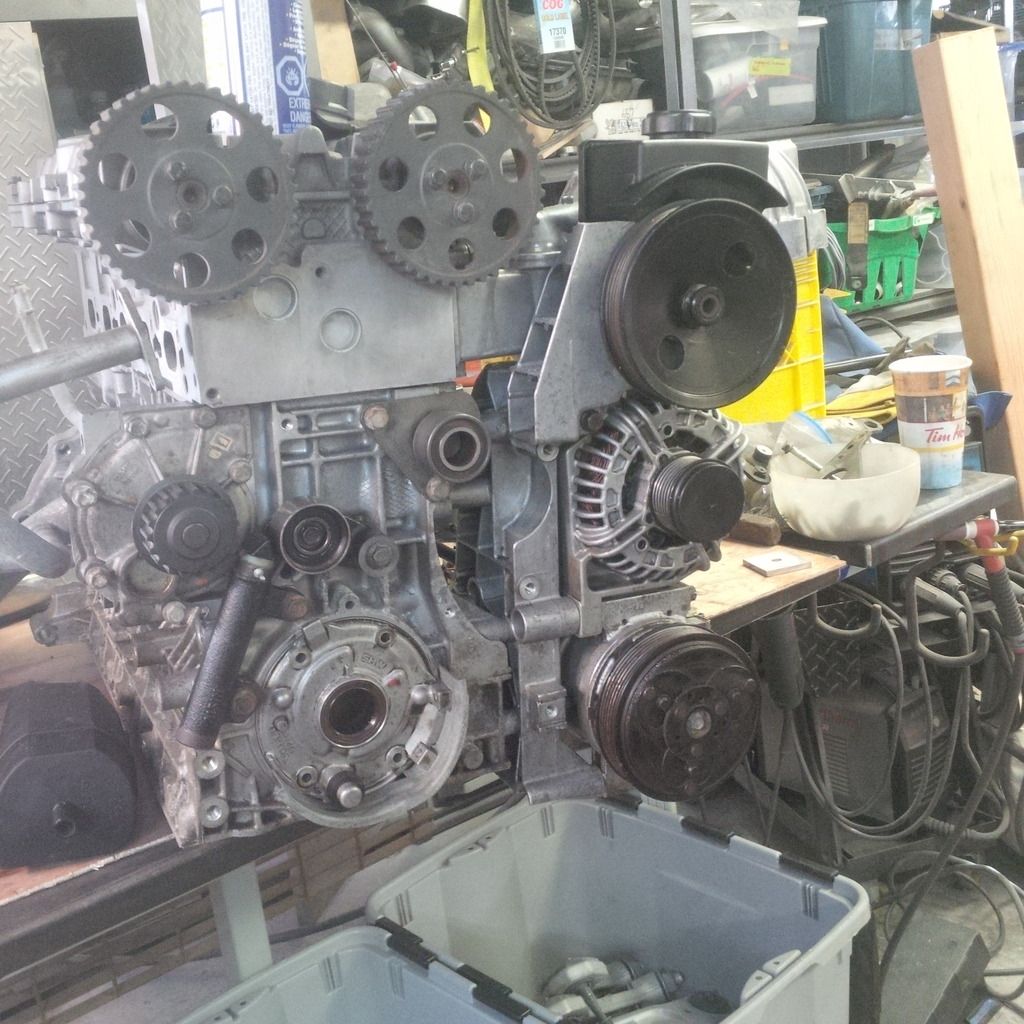

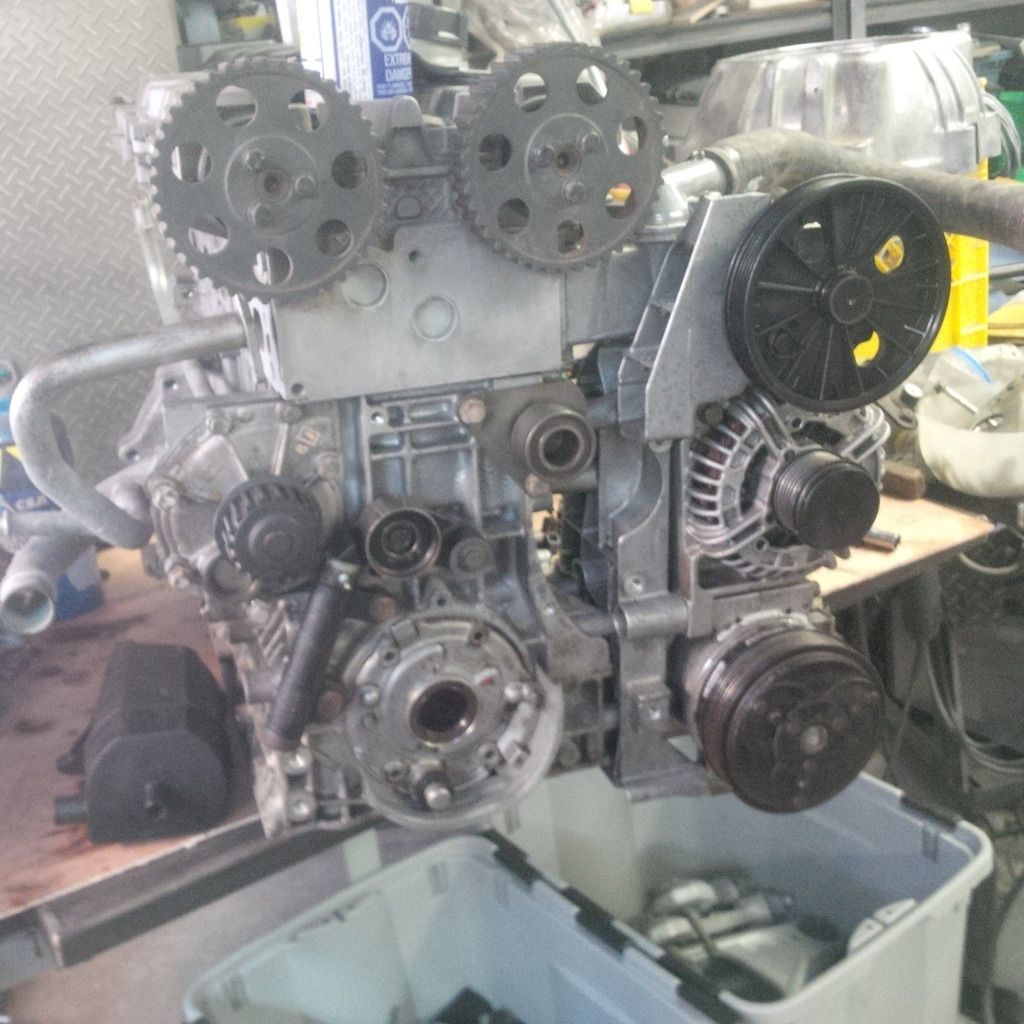

So to get this pedal cluster installed, I really have to mock up the engine and dare I say it...the transmission. Dammit. I was hoping to do this in the next step. So out of the shed the engine comes and I get started.

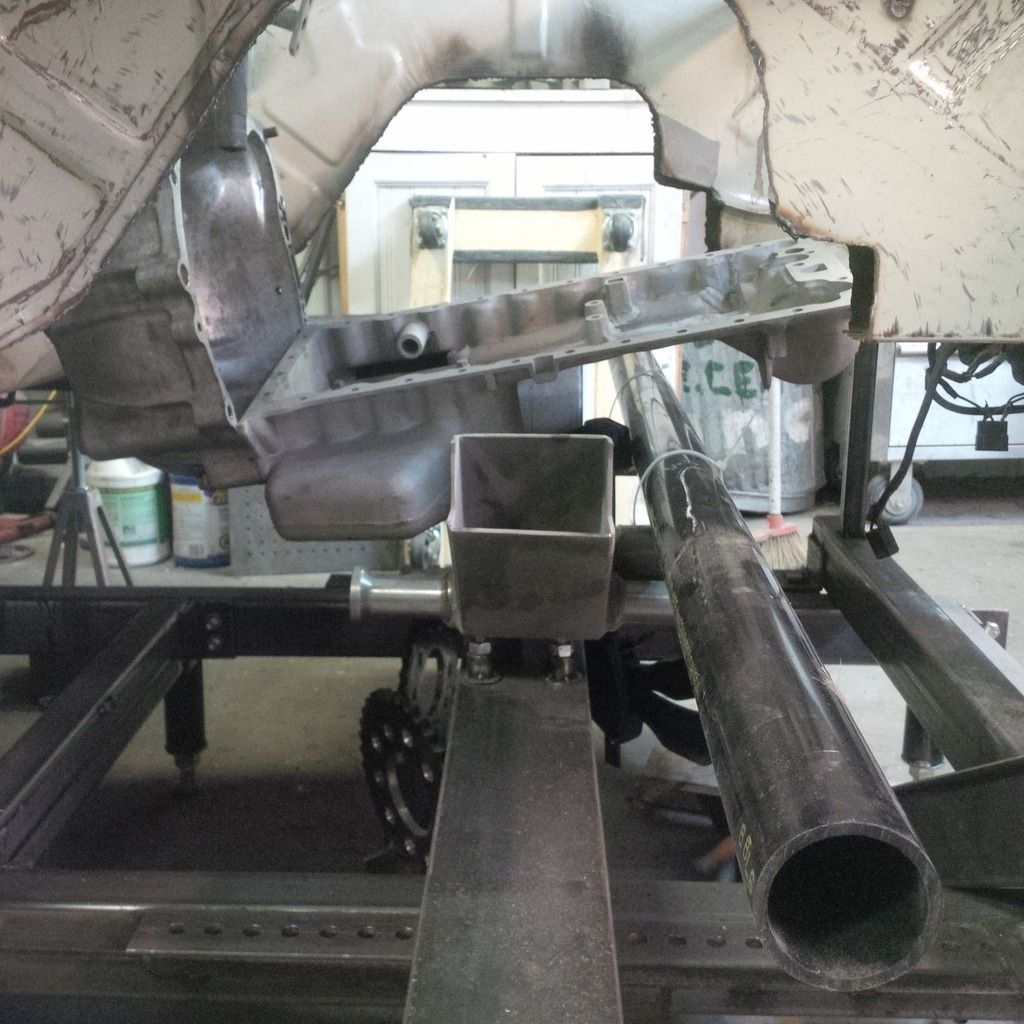

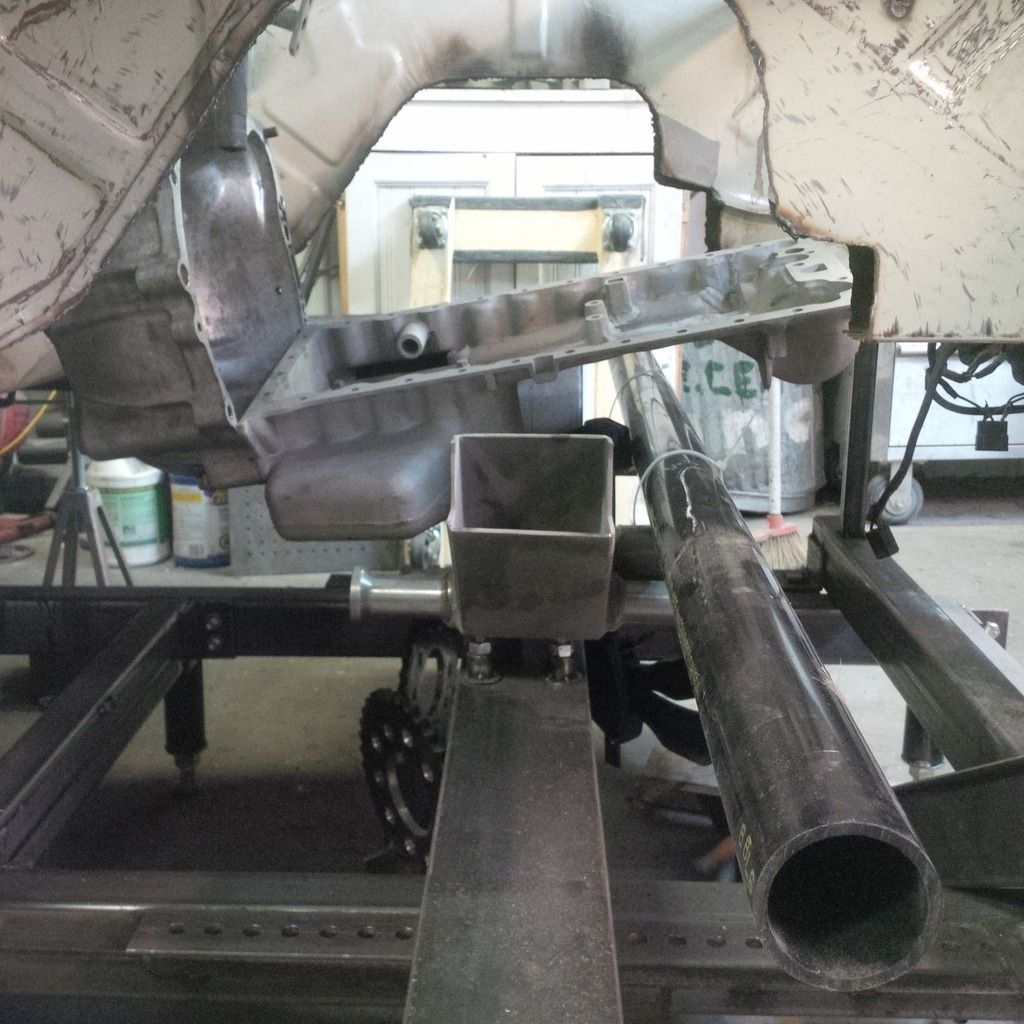

Oh boy...that's not going to work...firewall is going to need modification big time.

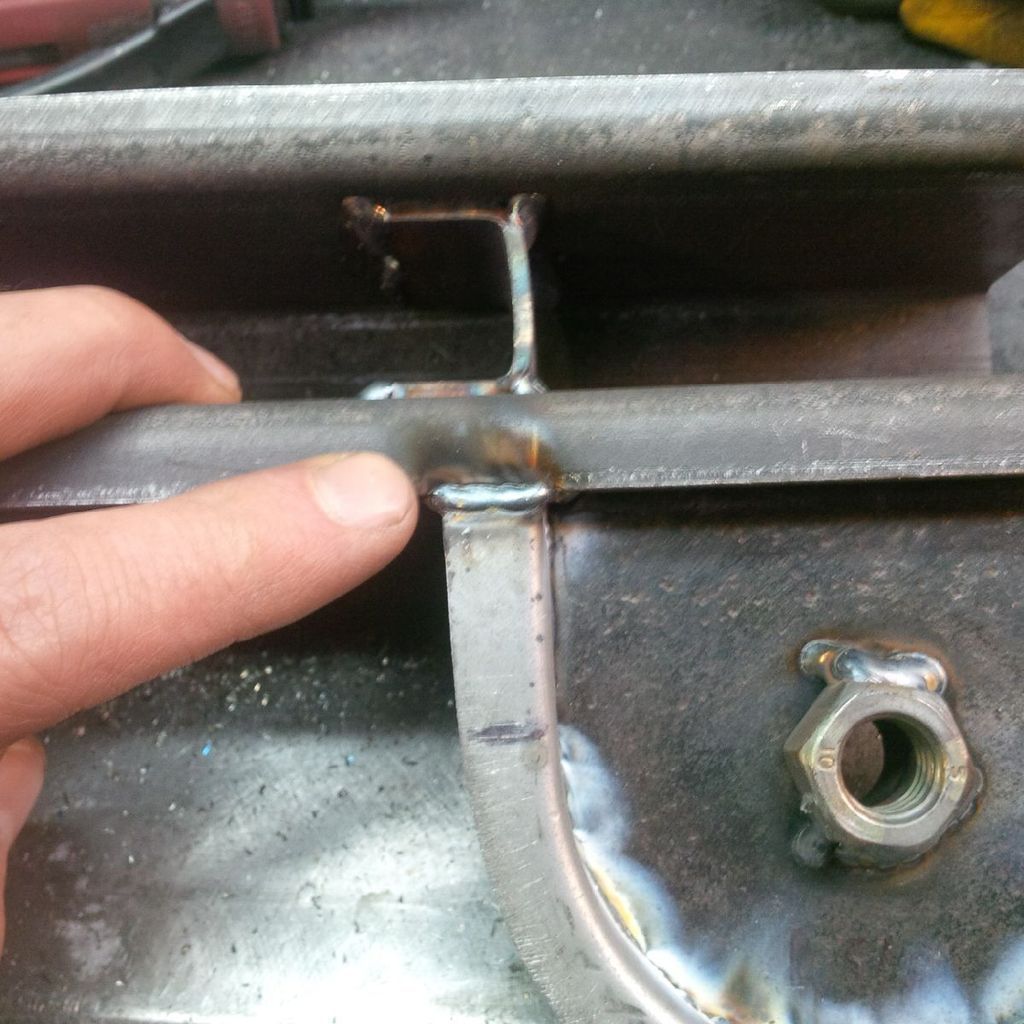

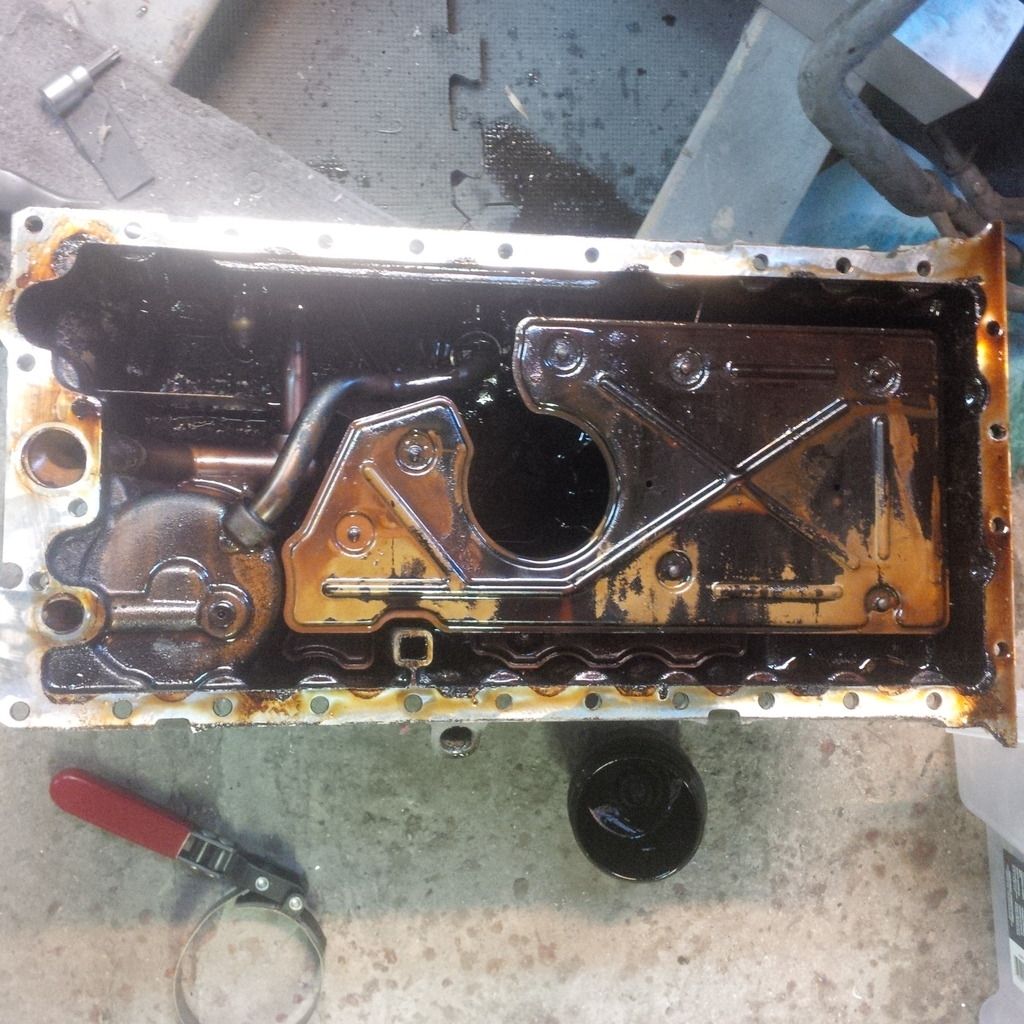

I suspended the pan on the wiring harness binding strap (finally something they're useful for) and had a look at the clearance problem.

It's gotta go down, but you get the idea.

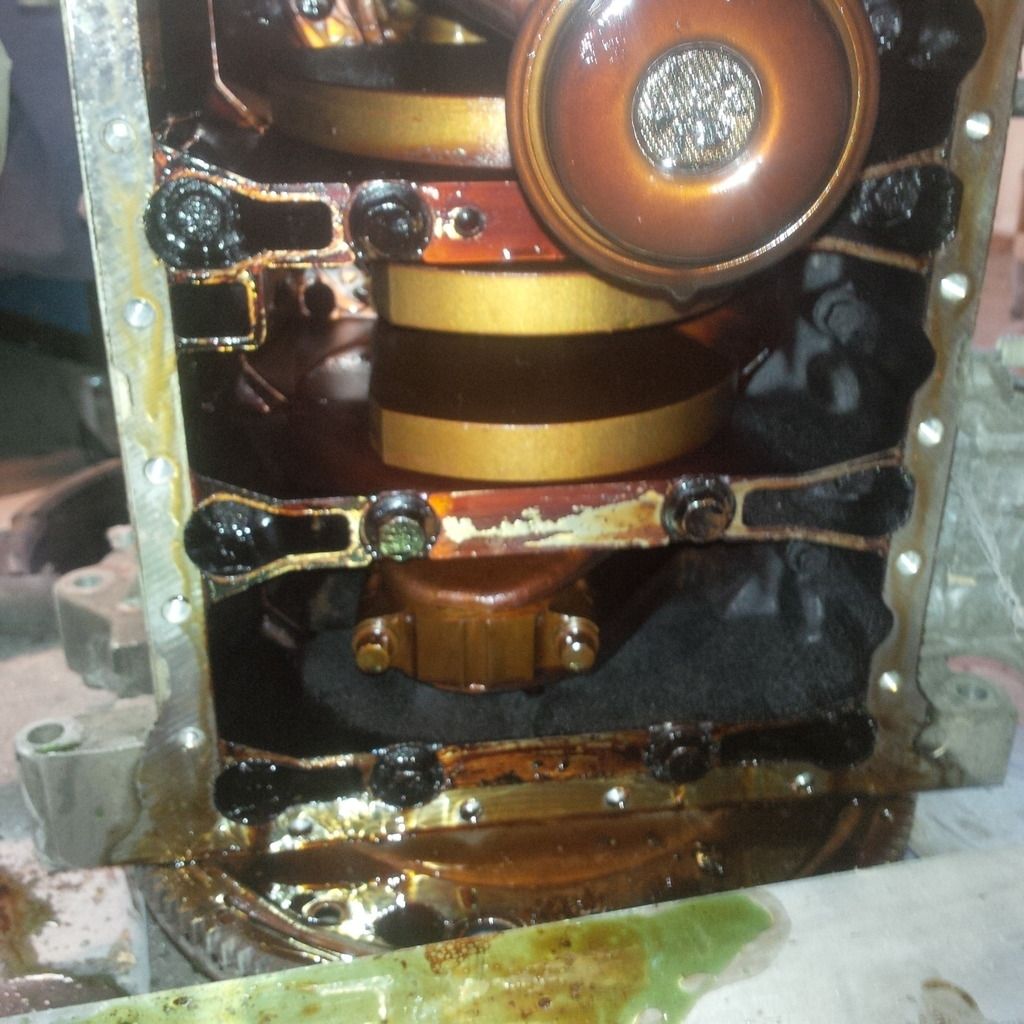

A look closer to the back.

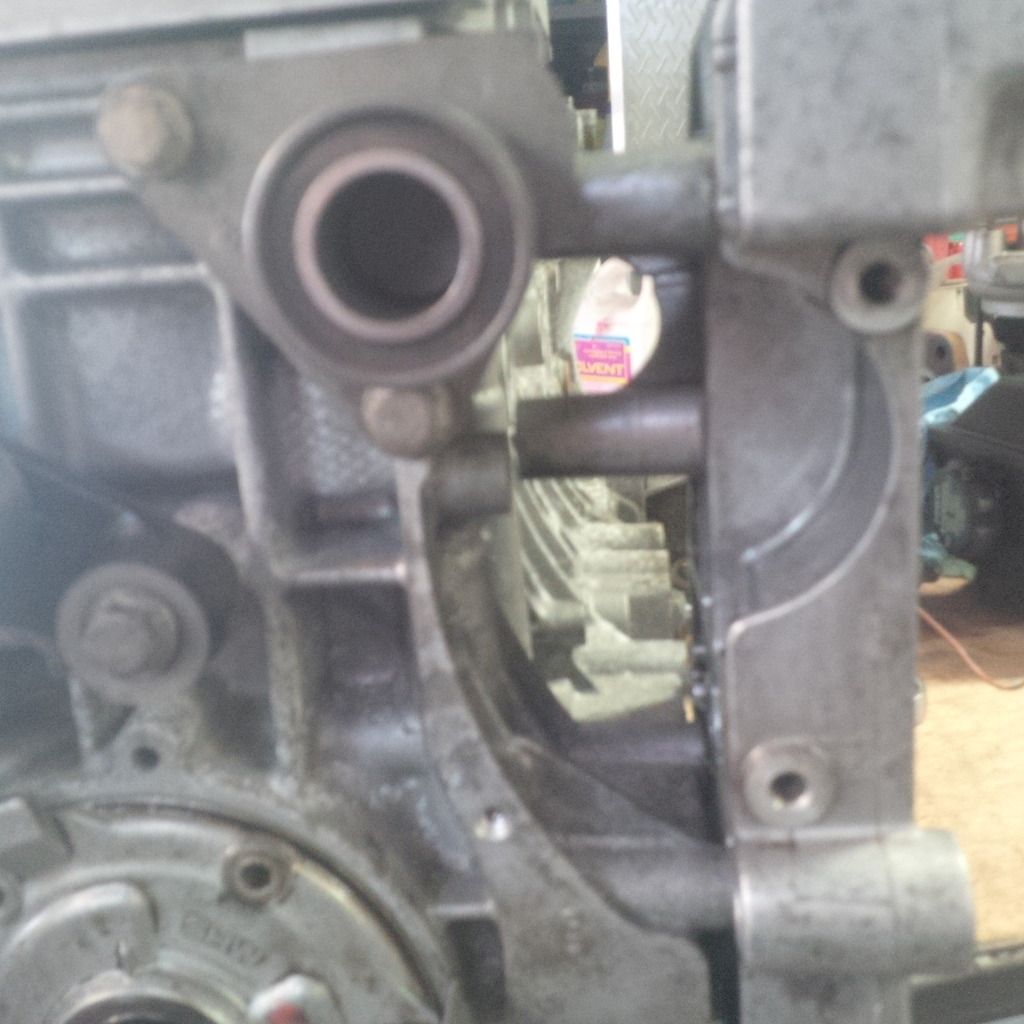

Starter is mounted high...and this presents some issues with clearance on the firewall.

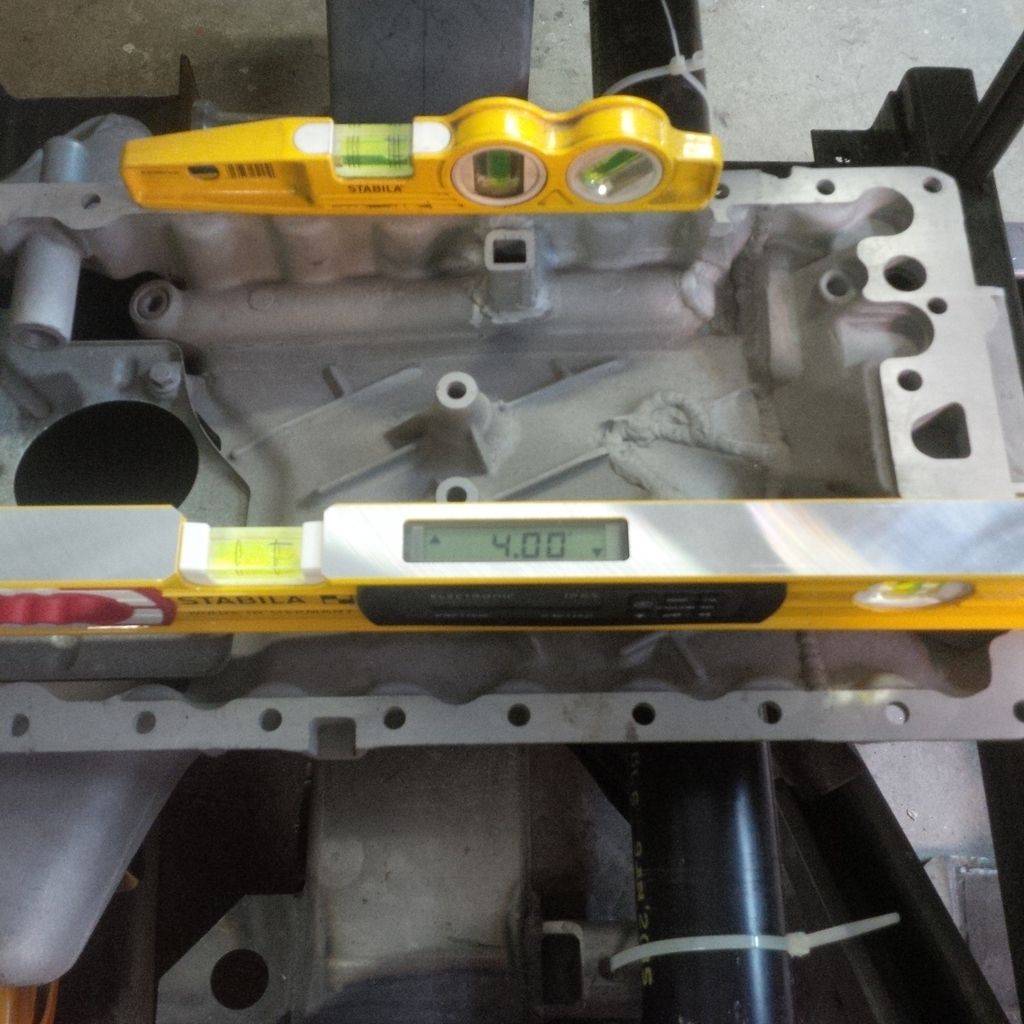

Enough with that play - it's clear that the firewall/engine/trans has to come first...then the pedal cluster. So the trans is going to have to come out of hiding and get stripped soon...like this week soon. I took the bell housing off the oil pan and levelled it in both dimensions. With a bit of ABS pipe serving as my steering rack and the cross member installed in place, I put the pan on to see where my engine clearance issues will be.

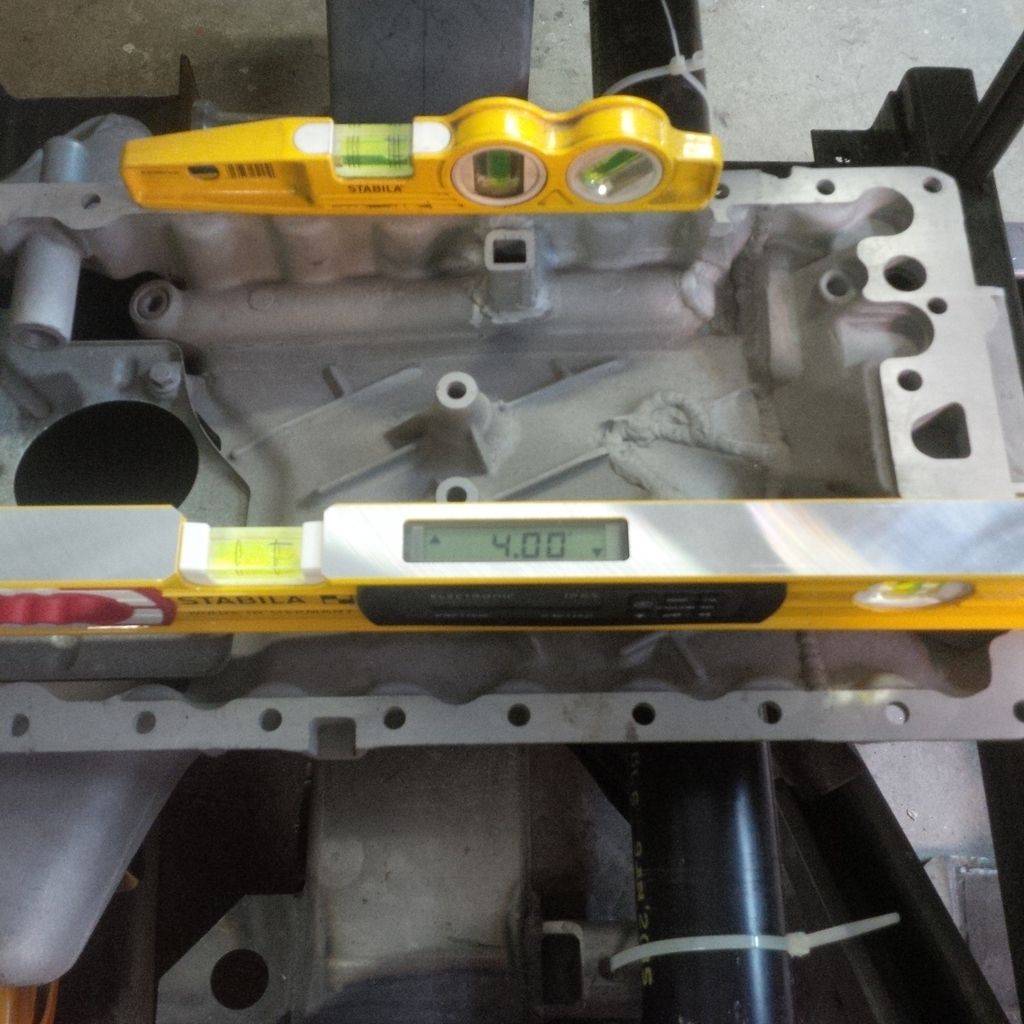

When I set a laser line up at the crank level, it was clear that the height of the steering rack is going to cause me a few issues. I expected as much, so no real surprise - the centre of the crank would be at the top of the tunnel, that's no good. Engines don't run level anyway...they all (pretty much) tilt to the rear to get some angle on the drive shaft u-joint. So I set it up at 3 degrees down...not enough, then I tried 4 degrees.

This pic shows the level at 3 degrees...I didn't take a side shot of 4 degrees.

So that's where we sit.

Things I know:

1. The real rack needs to go on the cross member with the rest of the parts.

2. The transmission needs to be bolted on the bell housing and the whole mess fitted in a real mock up.

3. More sheet metal needs to be cut/modified/put back together than I thought.

4. The pedals will have to sit for a little while as the rest gets sorted out.

In the mean time, the heater is now out as is the rest of the firewall junk. At least that got accomplished.