Well, after another week of work, we're just about ready to wrap up the rear cross member and get it welded. I have to be away next week for work and this coming week won't see much progress, but after I get home, I should be ready to roll.

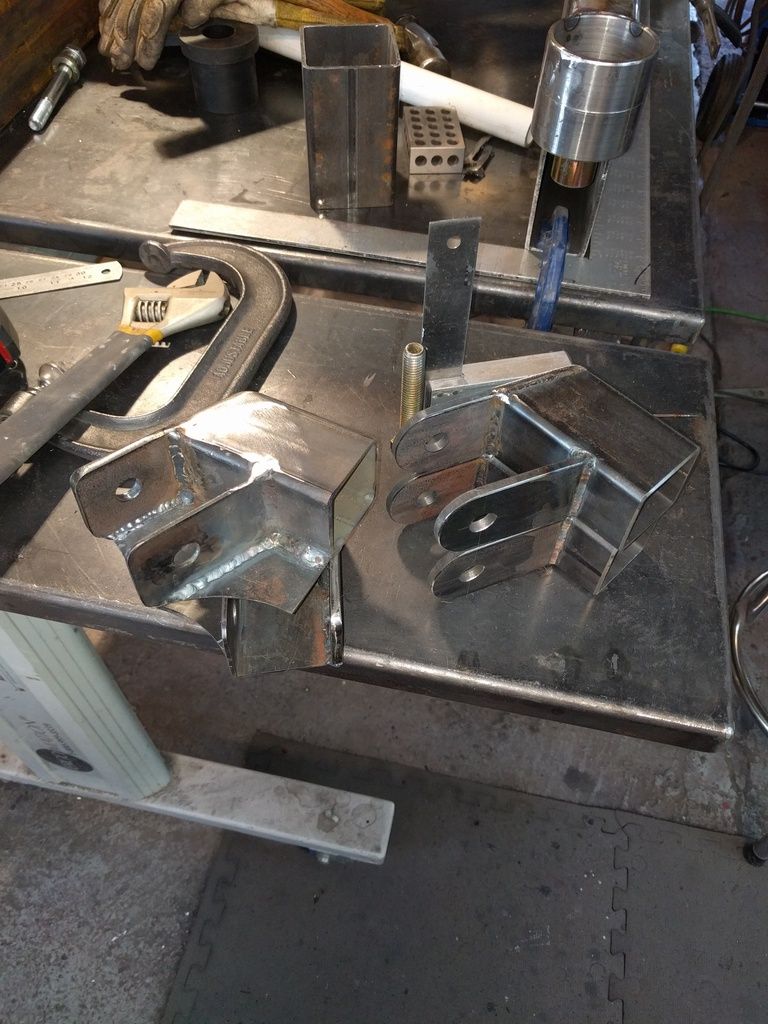

The next part that had to go was my fabricated cross member that held the differential snout. The one that I built didn't locate the toe arms correctly and I really wanted it gone as it just couldn't be fixed and not have it look like I hacked it.

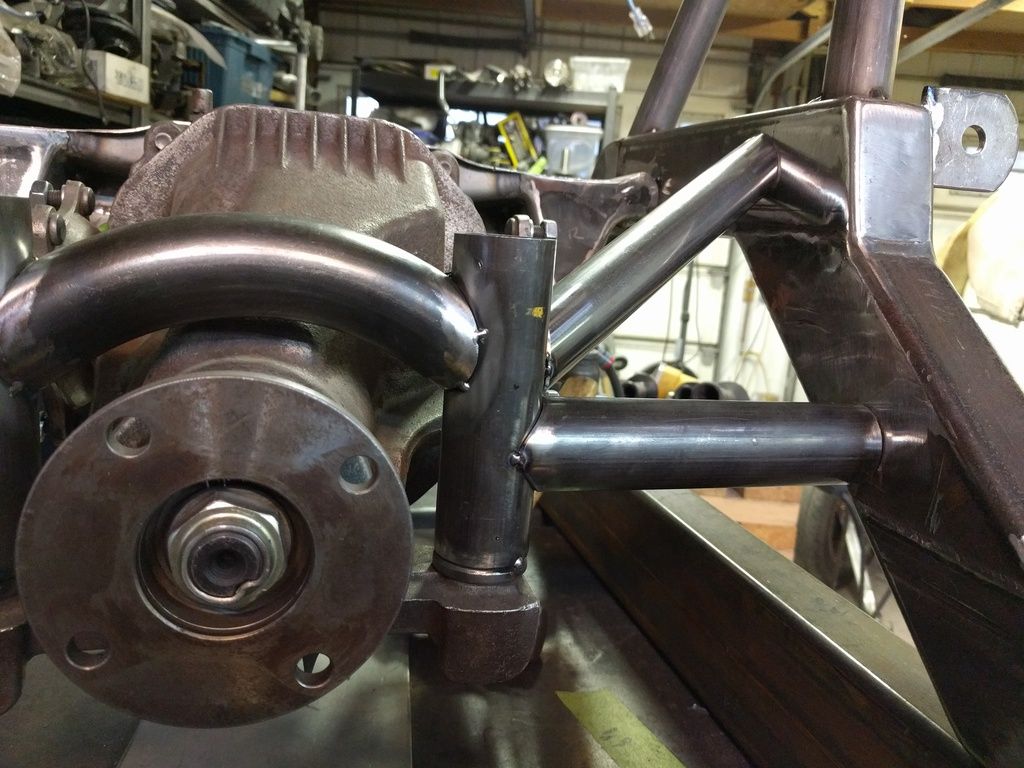

So here's the start.

I had cut the brackets off in the hope that I could salvage the part - but you can see the bottom plane is not level and was off 1/2" side to side. So off it came.

Then I started to make this.

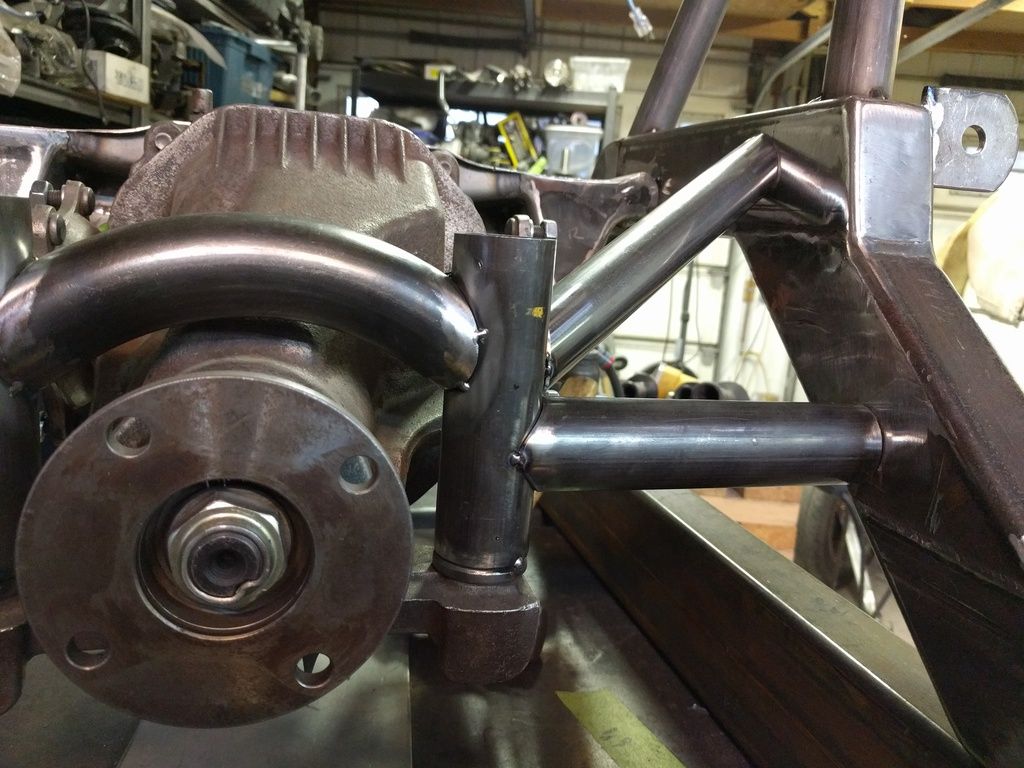

Join a few more tubes to handled both the toe brackets and the torque of the pinion trying to climb the ring gear.

And we have this. The bracket mount surface is perfectly level now.

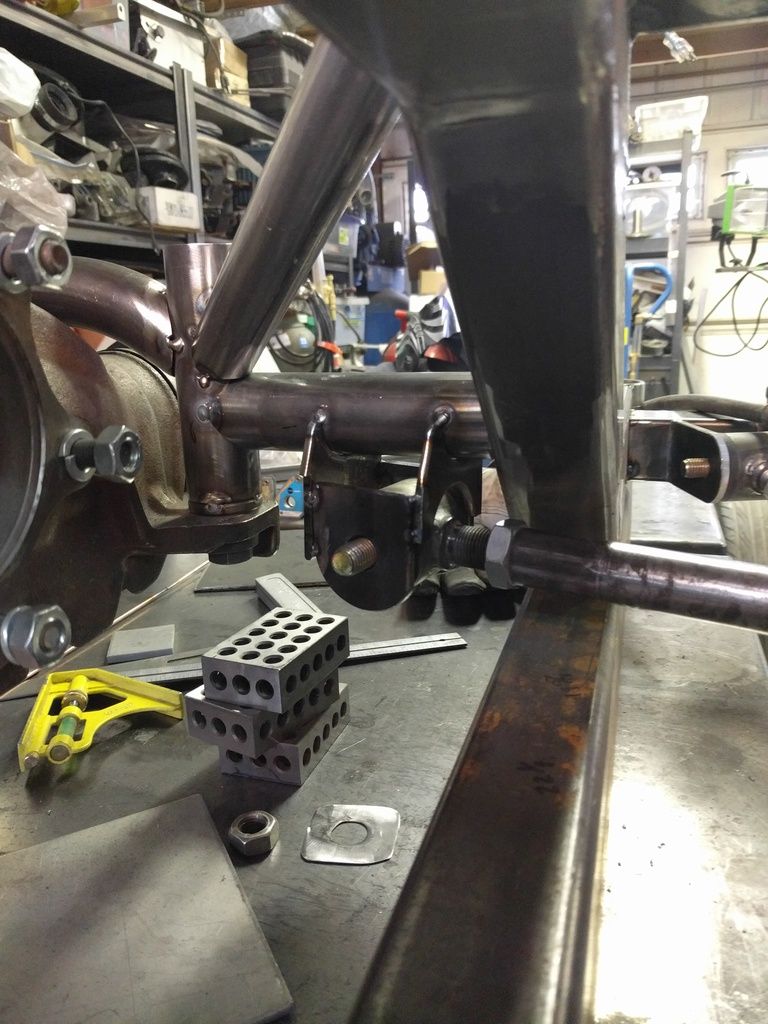

The proverbial K member. The tube ends will be cut and capped when welding. Mounts are 1/4" steel with TIG welded captured nuts.

That's a day worth of tube fitting.

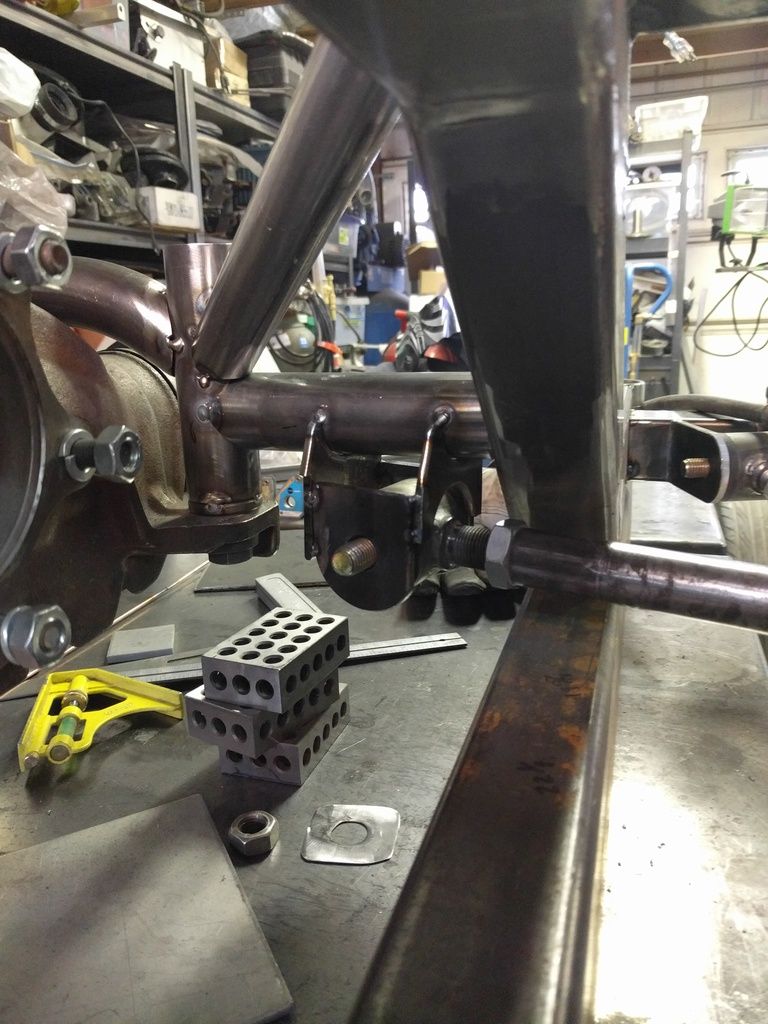

Toe brackets were fun to build as the two legs of the K are different lengths due to the offset of the pinion.

I built them longer then trimmed to fit. Hole saw came in handy for fitting and getting it all tight.

This bracket is mostly controlling motion to the outside/inside in an effort to keep the tire from toeing in or out. The way I had to fabricate it wasn't the way I wanted to do it, but there wasn't any other way to do this and still have things clean and free of areas that will collect dirt and moisture and if welded all the way around, it should be fine.

I left a mostly open corner on both sides of the bracket as that way I can get good penetration from one side.

Backside is notched for clearance.

Next up - fixing the coil over mounts.

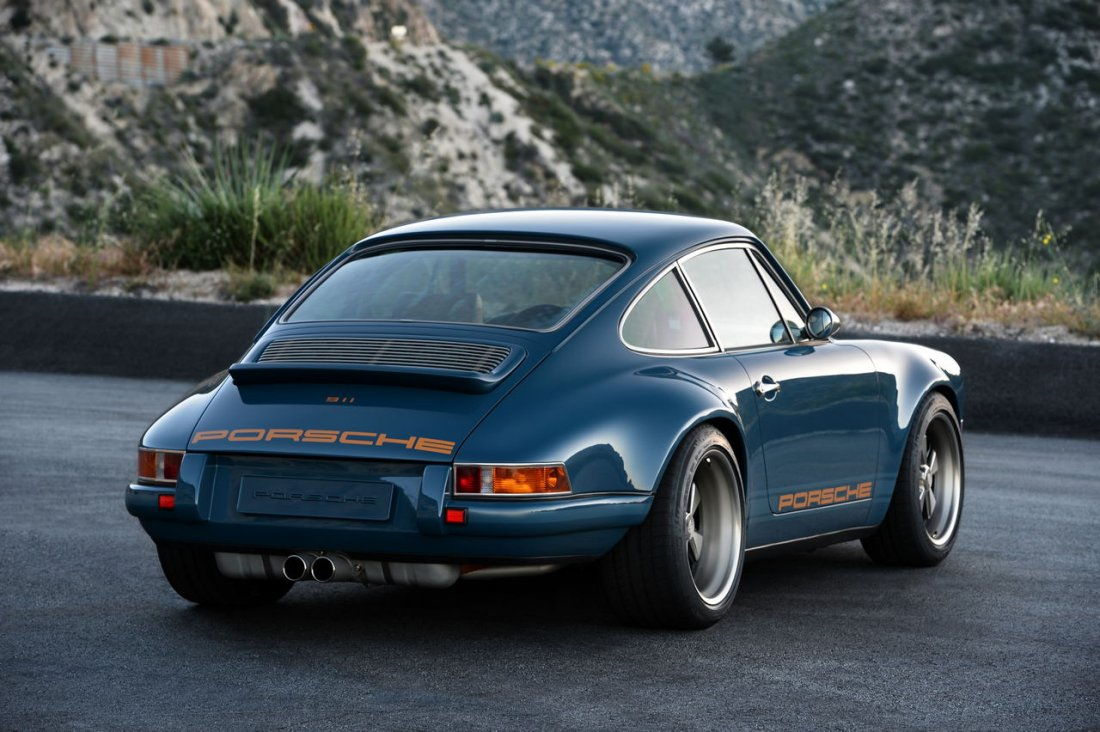

This was the closest emoji for confused I could find. I thought you were going with a titanium grey for a color? I like that blue though, looks like a 60's Volvo color.

This was the closest emoji for confused I could find. I thought you were going with a titanium grey for a color? I like that blue though, looks like a 60's Volvo color.