Just a quick update. The rear sub-frame is starting to come together. I took a couple weeks off to catch up other parts of the project and do some thinking about the problem. If I had kept the fancy frame curves, then significant parts of the back seat sheetmetal would have to be hacked for it to fit. Or I could just weld the turn using a simple angle and only have to create a little clearance (how little will be determined when I test fit the part). So with this little detail off my mind, it was time to spark some stuff up and get this rolling.

Here's the frame rail welded (I didn't take photos of that mid stream...keeping tube straight is tricky and most people will never weld a frame because they're smart).

I had dreams of using Welder's Series weld on tabs for my suspension mounts, but as you can see here, there wasn't enough bearing area on the bushing. So I made my own - dammit.

They will work for this part as the crush sleeve is held and is proud of the bushing side. It's meant to flex.

The rear anti-dive is apparent in this shot - oh and my tabs were fabricated in a few minutes with the plasma (couldn't work without that tool). The tabs will be TIG'ed and then a cap applied to give more lateral support as a gusset to the outside just isn't going to work.

The batwing section on the back fit right in with minimal cutting. I've since stripped the paint and will finish the fab work on the weekend. No way to sandblast the part as the wax undercoating Toyota used is fabulous protection against ham-fisted car hackers. Had to strip the part chemically.

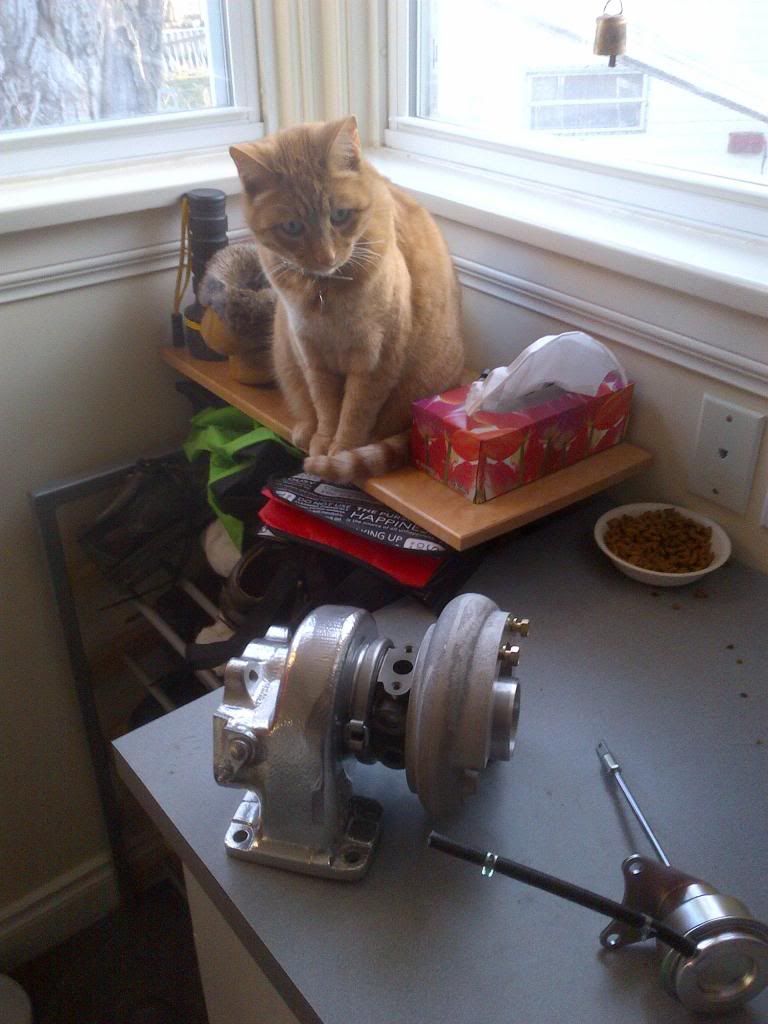

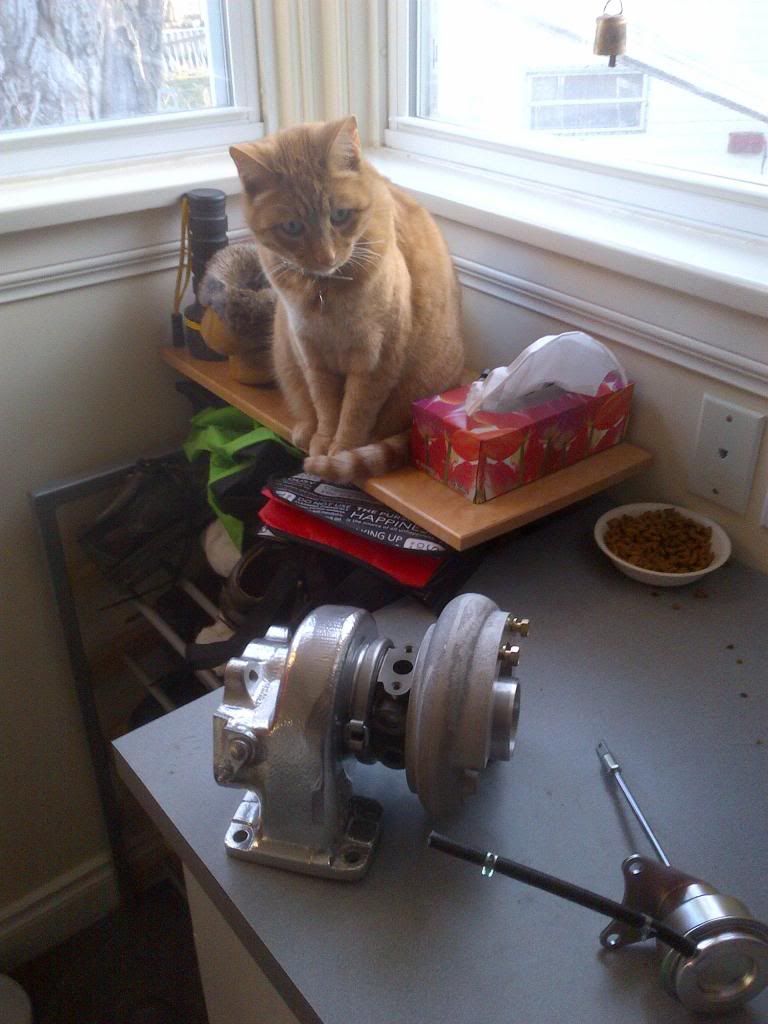

Then the UPS dude brought me this:

Kitty approved.

Apparently, Hahn Racecraft was drunk when they clocked the turbo...no way the wastegate fits. On the upside, it's forced me to look inside the centre cartridge and figure out the drains, feeds etc.

I'm not sure what to do about this little issue.

Wastegate exit on the left (note ceramic coating is only on the outside).

Here's the flapper valve closed.

And open.

At full open it hits the plug they welded in to block off the divided exit. If there was a lug on the exhaust mount face, I'd drill and tap it and cut that plug out of there...but there isn't.

Shots I was trying to find on the internet but couldn't - here's the hotside TD05-20G

Inlet (and that compressor housing is calling me for a quick polish).

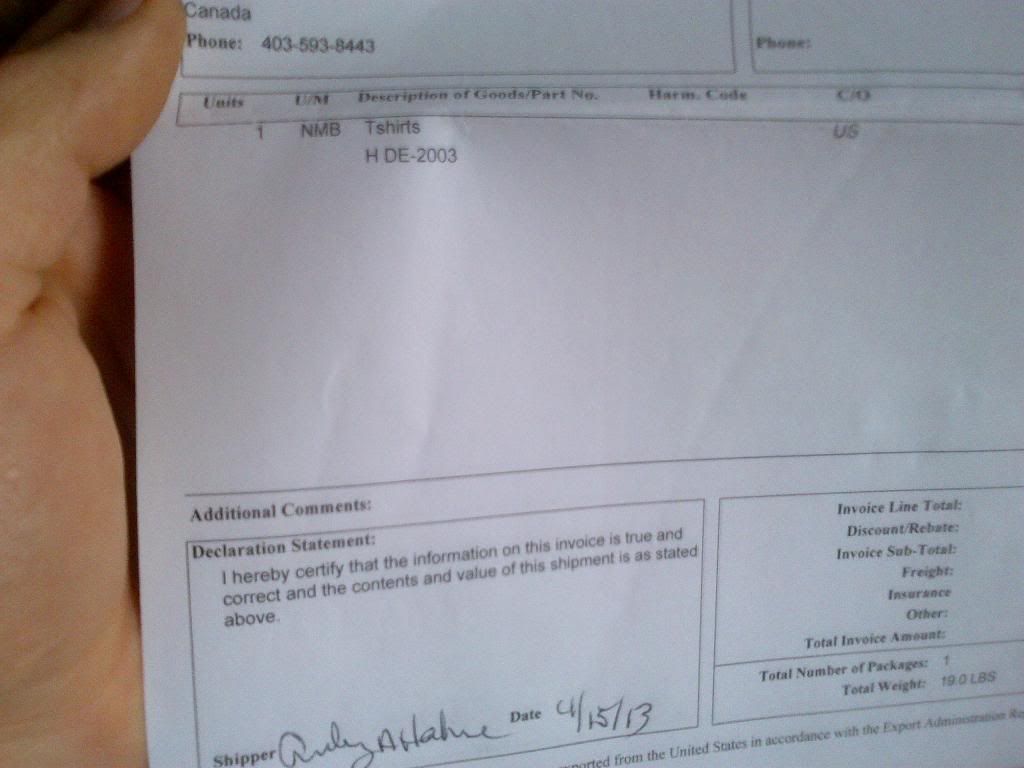

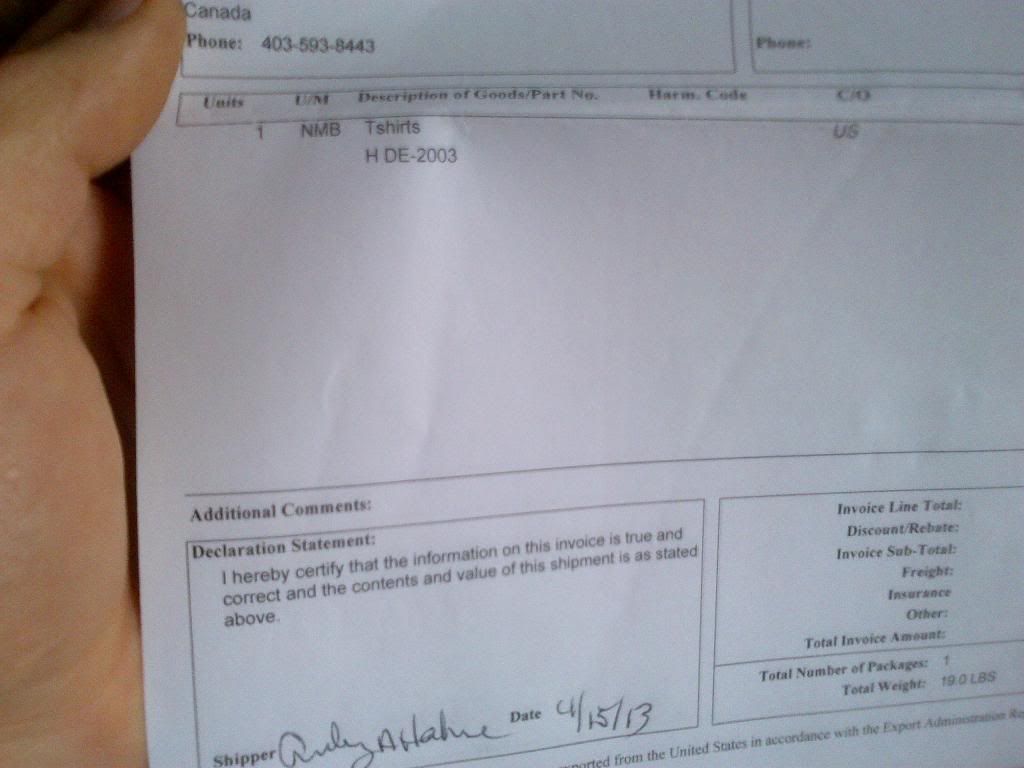

Oh, and here's the reason it took over a week to clear customs...apparently, Hahn thinks turbos are T-Shirts...WTF

That's it for now.