OK - Time for an update. Honestly, I'm hammering on this thing like a drunken blacksmith but it just doesn't look like I'm making progress. One of the problems is that I keep running into little snags related to how much time has passed between purchasing and installing parts. I started writing a separate build journal for all the details several years ago, but most of this predates that (or precipitated) effort.

Exhibit A - The Case of the Buggered Steering Rack.

In one of the videos I mentioned the surreal experience of talking to Tony Woodward of Woodward Precision Power Steering. Great products but you'd better be ready for the oddest conversation. Maybe all steering guys are like this? So I called on the 15th of Feb, 2012 with the need for a custom power steering rack as I wanted to get the rack lower so the engine would sit down in the chassis. The old rack was up around the crank and an inch really was going to matter. So with some string, I "measured" where the rack pivots should go (he'd need this measurement, and I try not to waste people's time.)...picked up my phone and credit card...and made the decision to buy this rack. The Canadian Peso was riding high, so buy it now and "save" later. So I get the boss (Tony) on the phone. I try to have a conversation where he would educate me on my options. He's on the shop floor working on things...we have about a 15 second discussion. It goes sort of like this:

Me: Hello. I'm building a Volvo with a Corvette C4 suspension...

Tony: Yes, I know exactly what you need. What are your pivot dimensions.

Me: What sort of rack do you think would be best?..oh and 21".

Tony: You don't want to steer too quickly for a street car - 2.36 turns lock to lock is fine.

Me: Interesting. What kind of servo or parts and things will I need to put this together?

Tony: Great, I'll pass you back to the billing people.

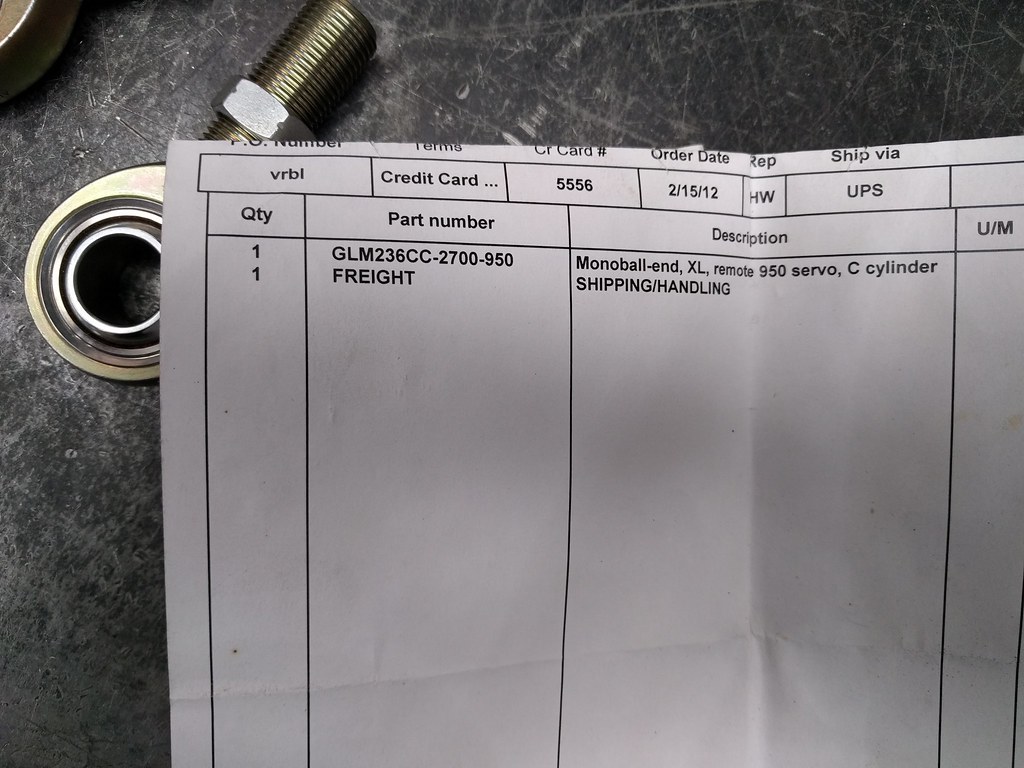

That's about how it all went. Parts come in. Look fantastic. I don't need them for years. Sit in the basement parts stash collecting dust.

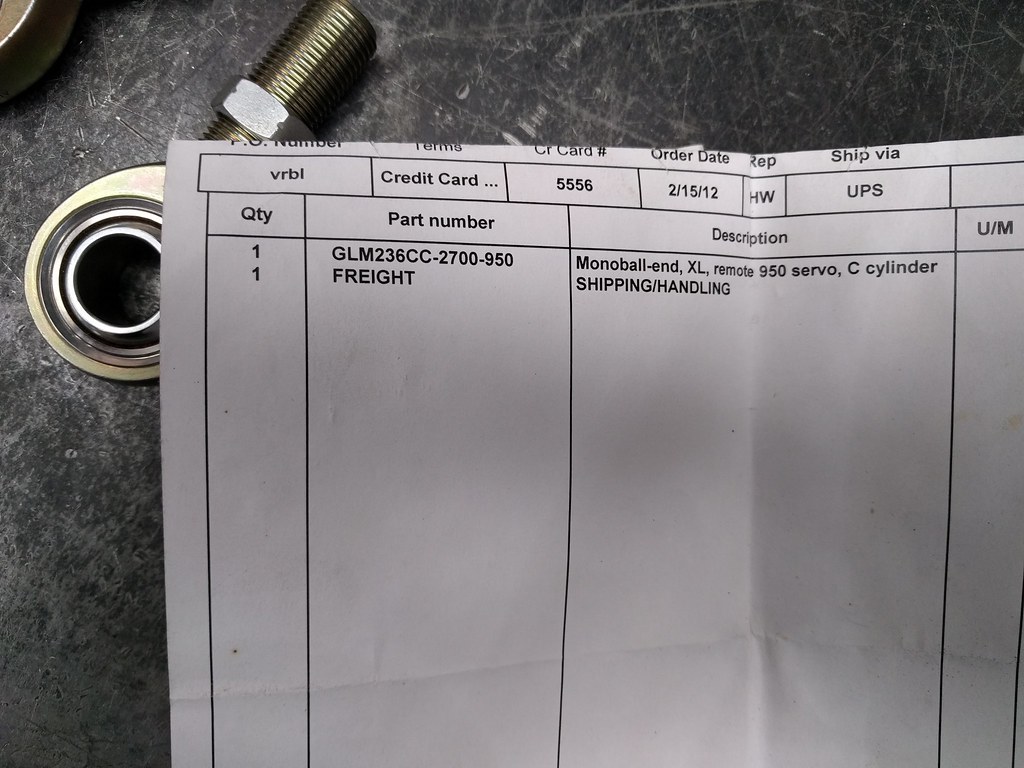

Scroll back to the picture of the bill - decoding the part number is critical...GLM is the style of rack, 236 is the turns lock to lock...C is the cylinder,

2700 is the pivot to pivot in inches, 950 is the servo.

I noticed this about 3 months ago when I was trying to look up the mount details and spoke to Tony on the phone again. I was wondering if the online instructions that required 3/8" plate for the mount was required. It is. I asked Tony about the rack as it wasn't supposed to be 27" pivot to pivot. He had no clue...I told him that I measured it and it was 21 - he reply's with "Well, it's 21" then!"

This is what causes stress people.

Alone on an island with bad paperwork and not enough knowledge.

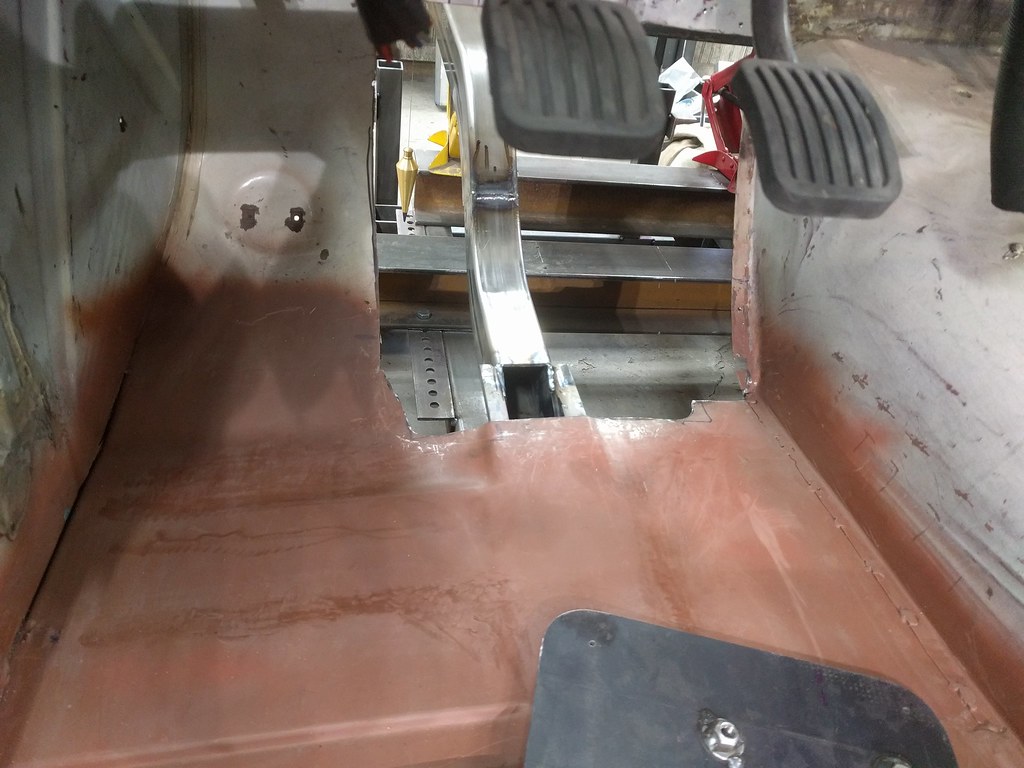

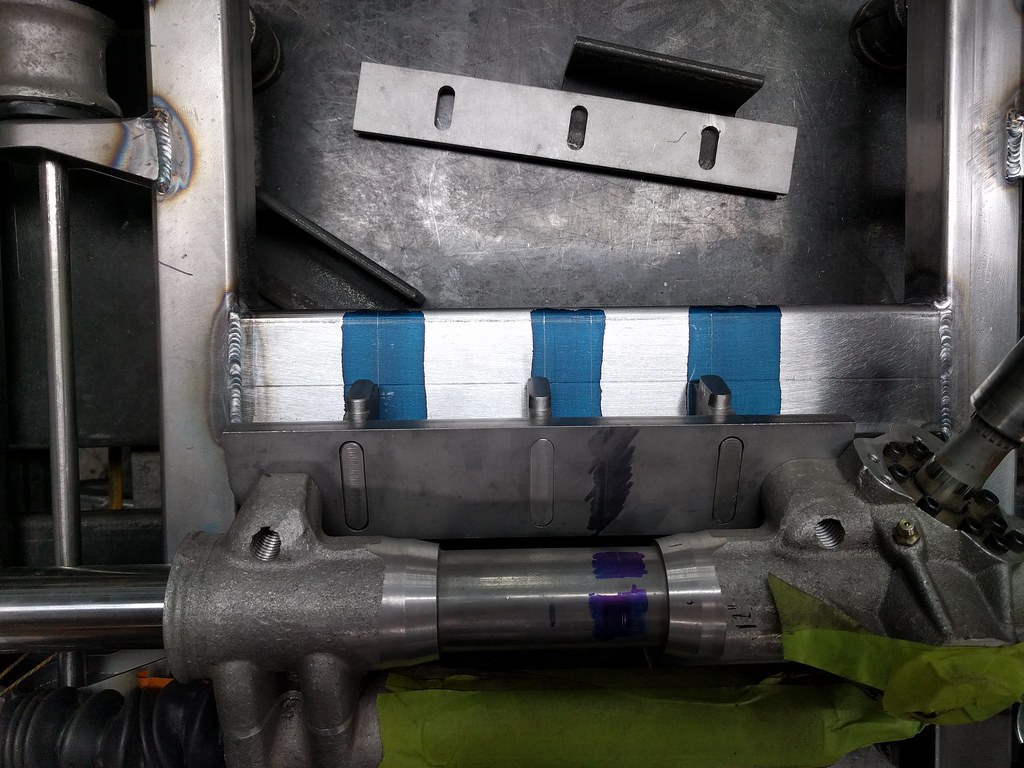

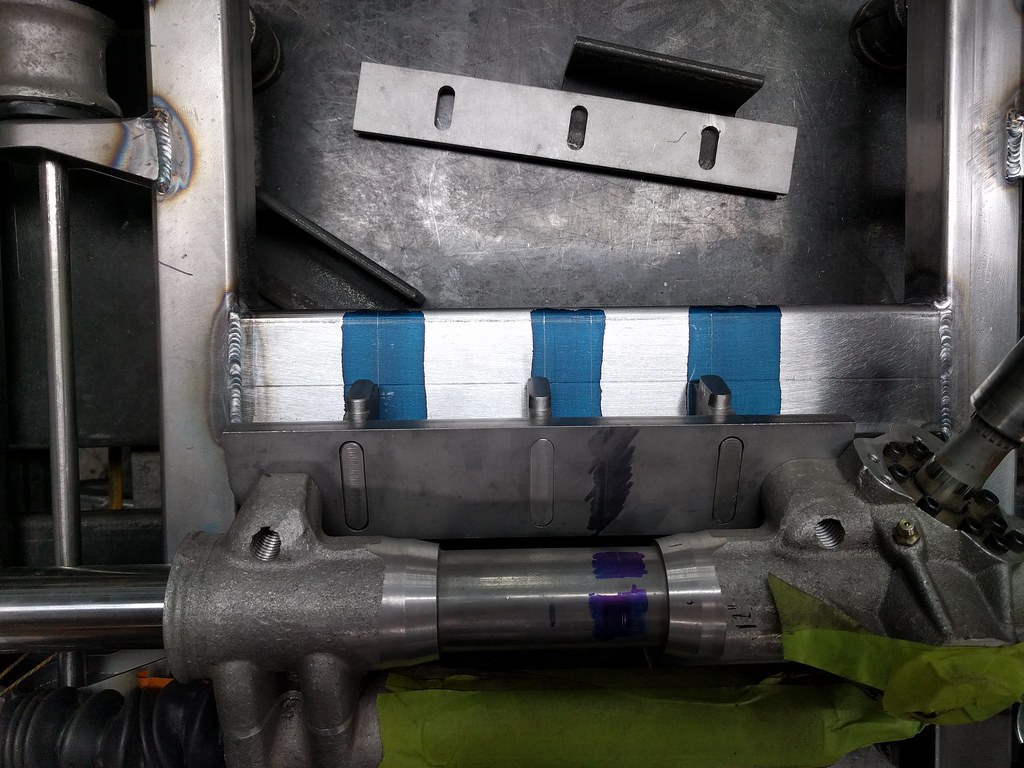

So I just put the rack on the bracket and tacked it on the frame.

Well, after I scribed a few layout lines.

I was very careful with these fits...in fact the parts only go in one way as I didn't square up the laser kerf. You have to tap it together when installed.

I'll cover the how's and why's on a future video.

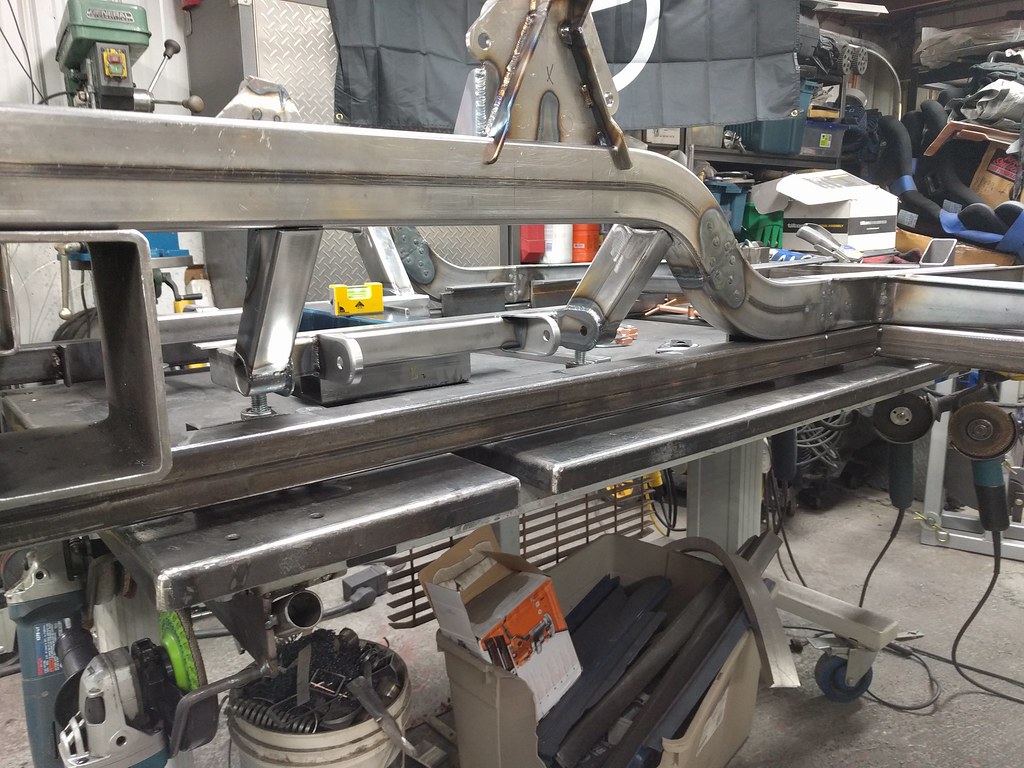

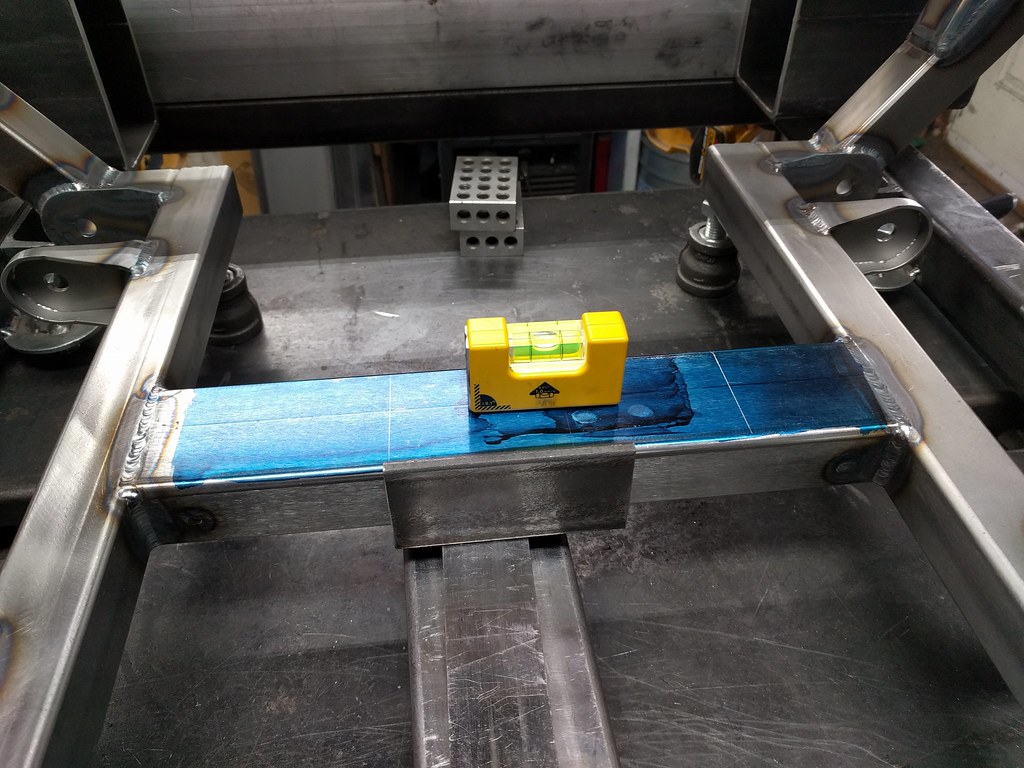

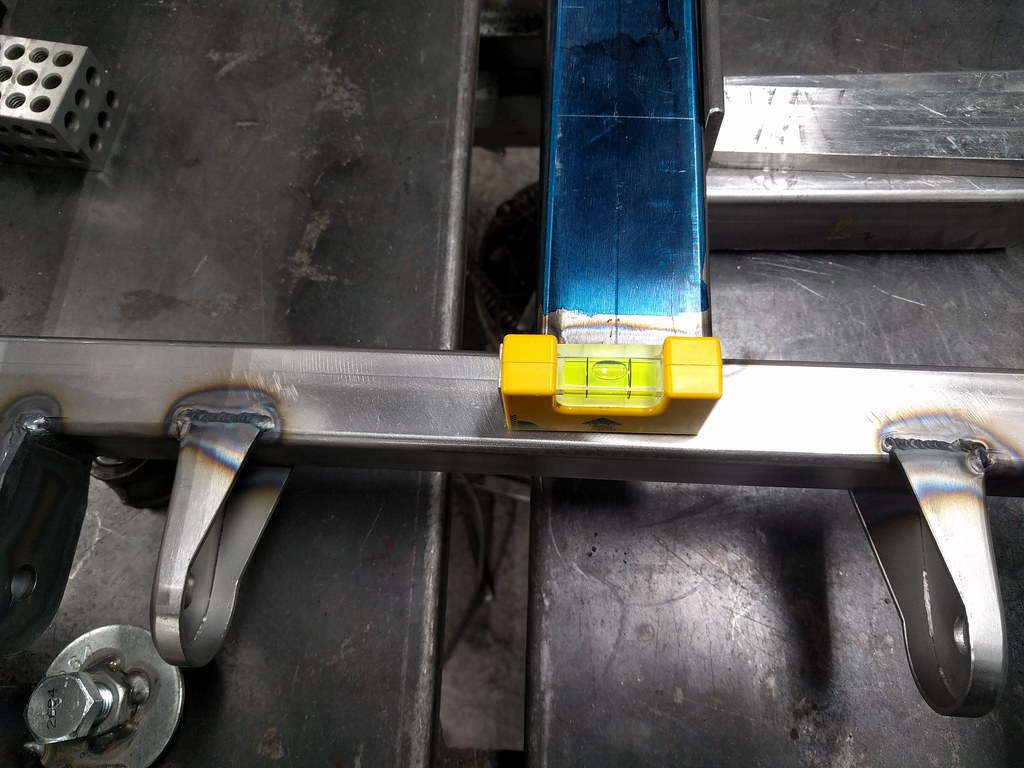

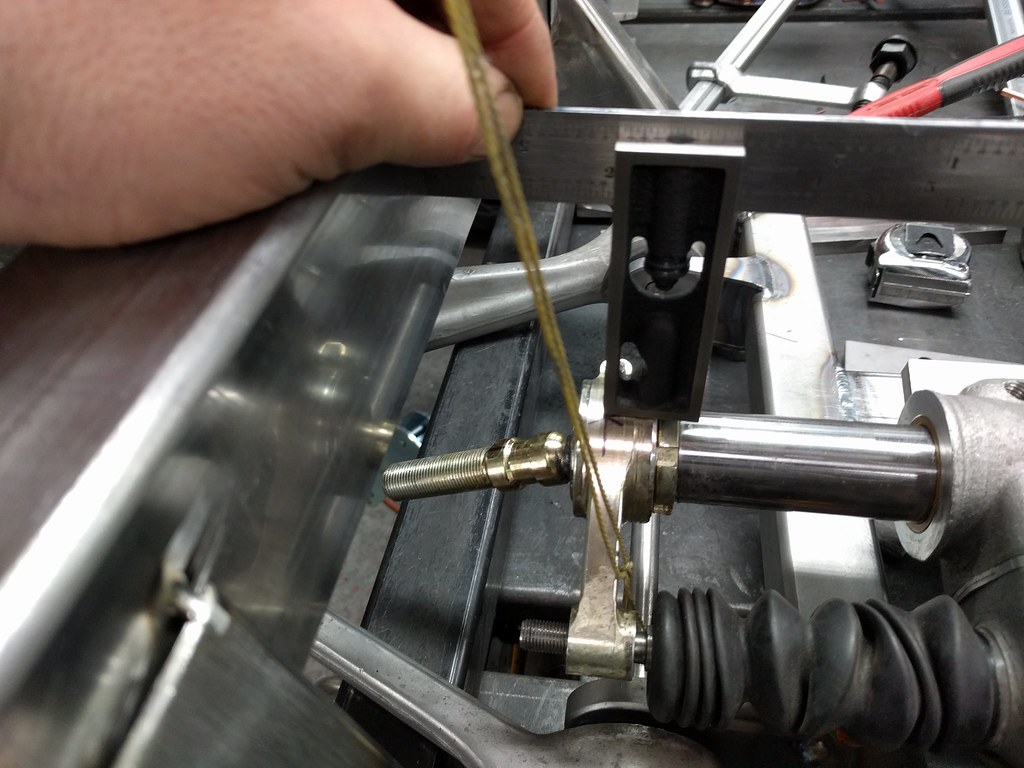

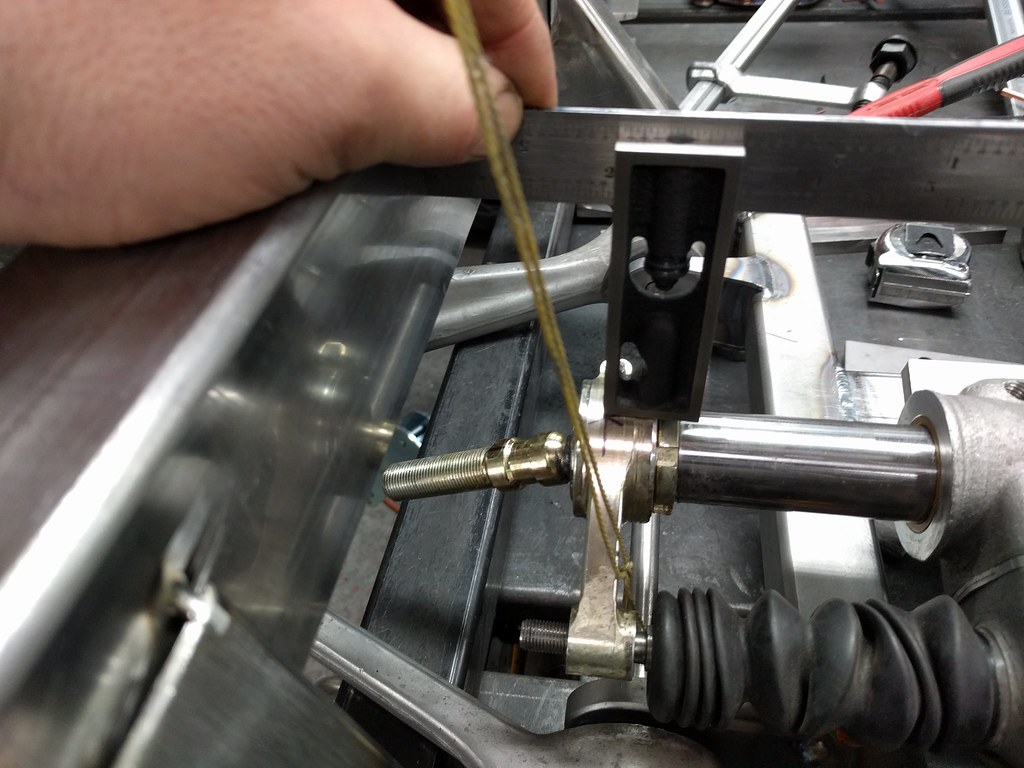

Then it was back to the string to check the pivot positioning and a little test of centre with the square.

It should be 2" from the frame rail to the pivot. Yup...that'll do.

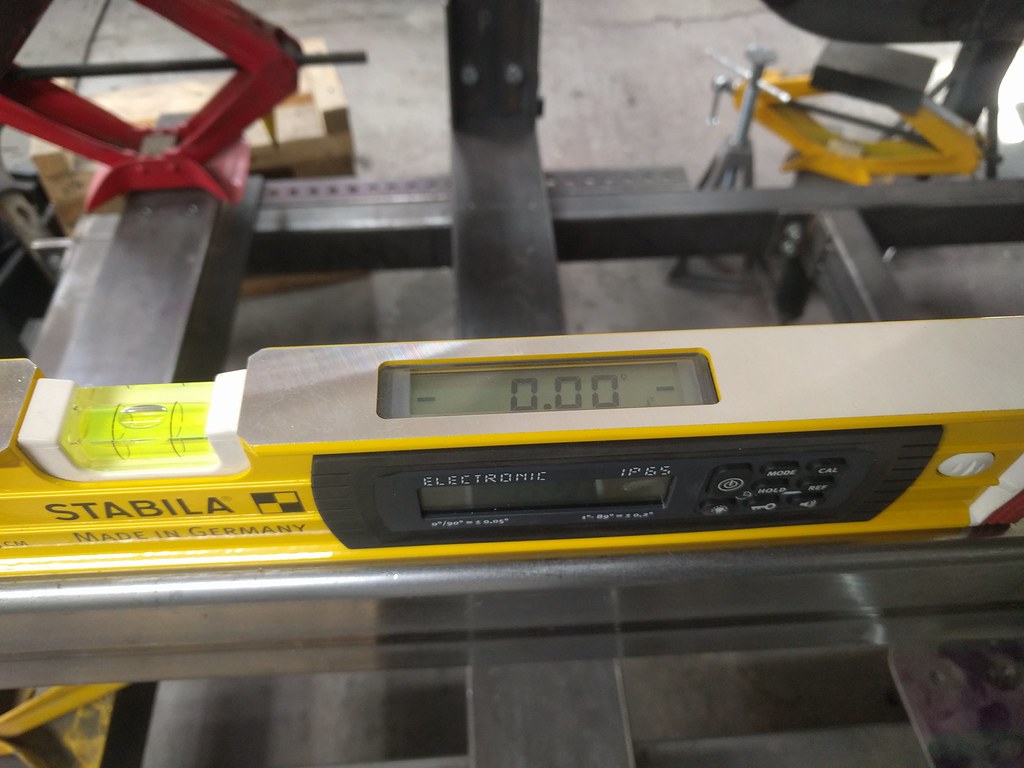

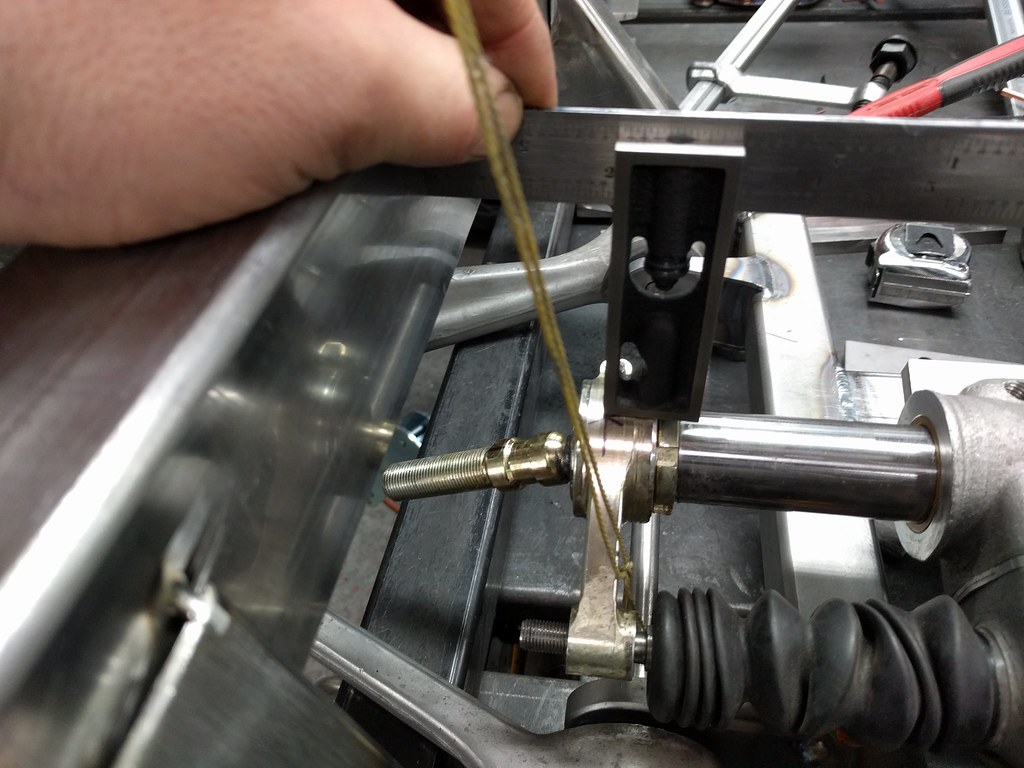

Now it's on to the coil over mount check. The design says 15° inclination.

That also...will do.

So that was where we were at about a week ago. I've spent the last week working out the suspension dynamics to buy anti roll bars and coil overs. I have stumbled and fumbled around with this as I'm working through it long hand, don't like witchcraft, and need to be able to understand what I'm doing (I'm not a software monkey - I'm a scientist dammit). So that's taken some time.

I may post the method when I understand it - but also understand that it's pretty niche market on the who cares scale.

So now you're caught up.