Sorry folks...I've been a bit busy. Time for an update post. After three weeks of hard work getting the molds prepped (see above video's) it was time to move on.

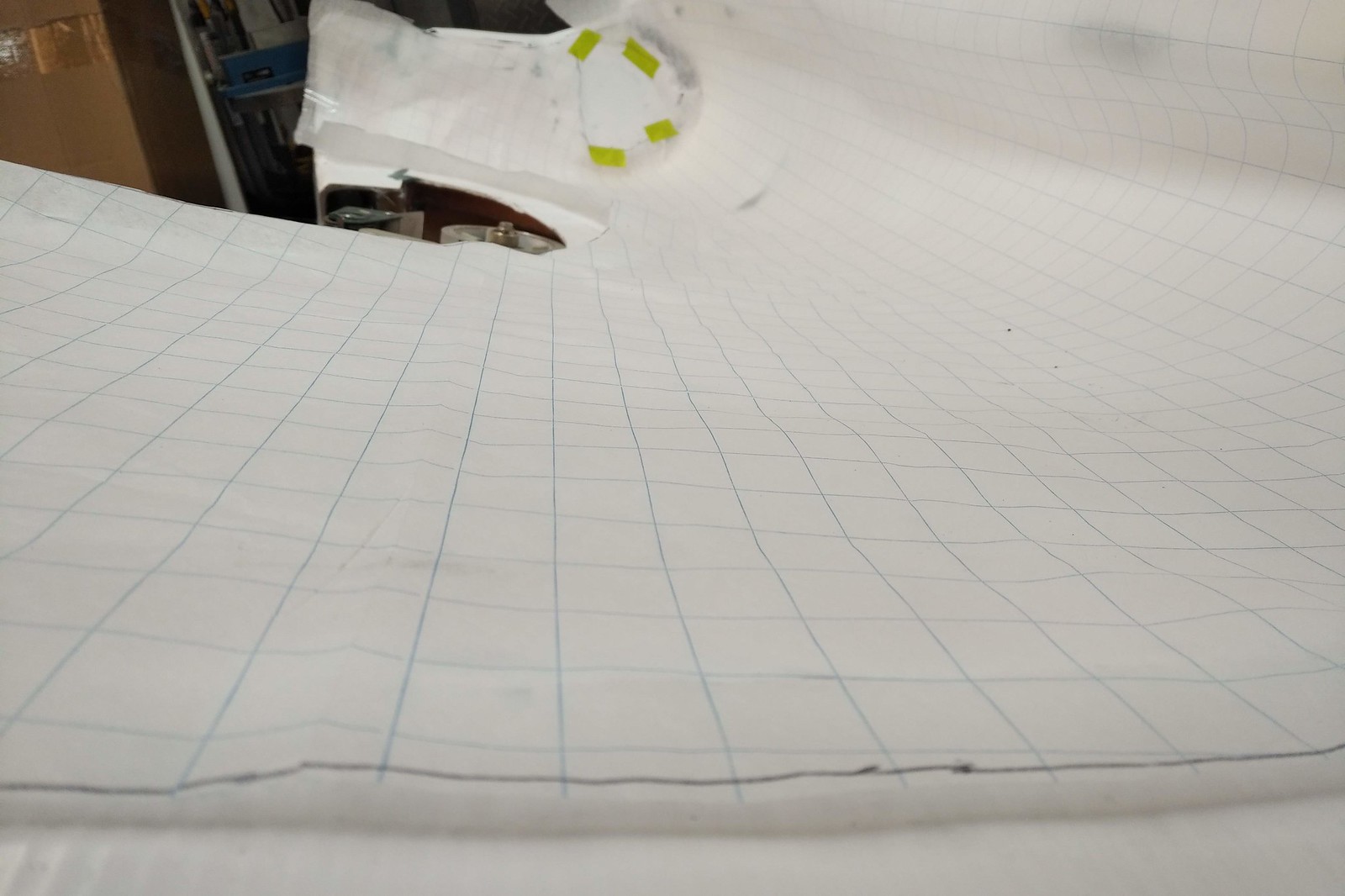

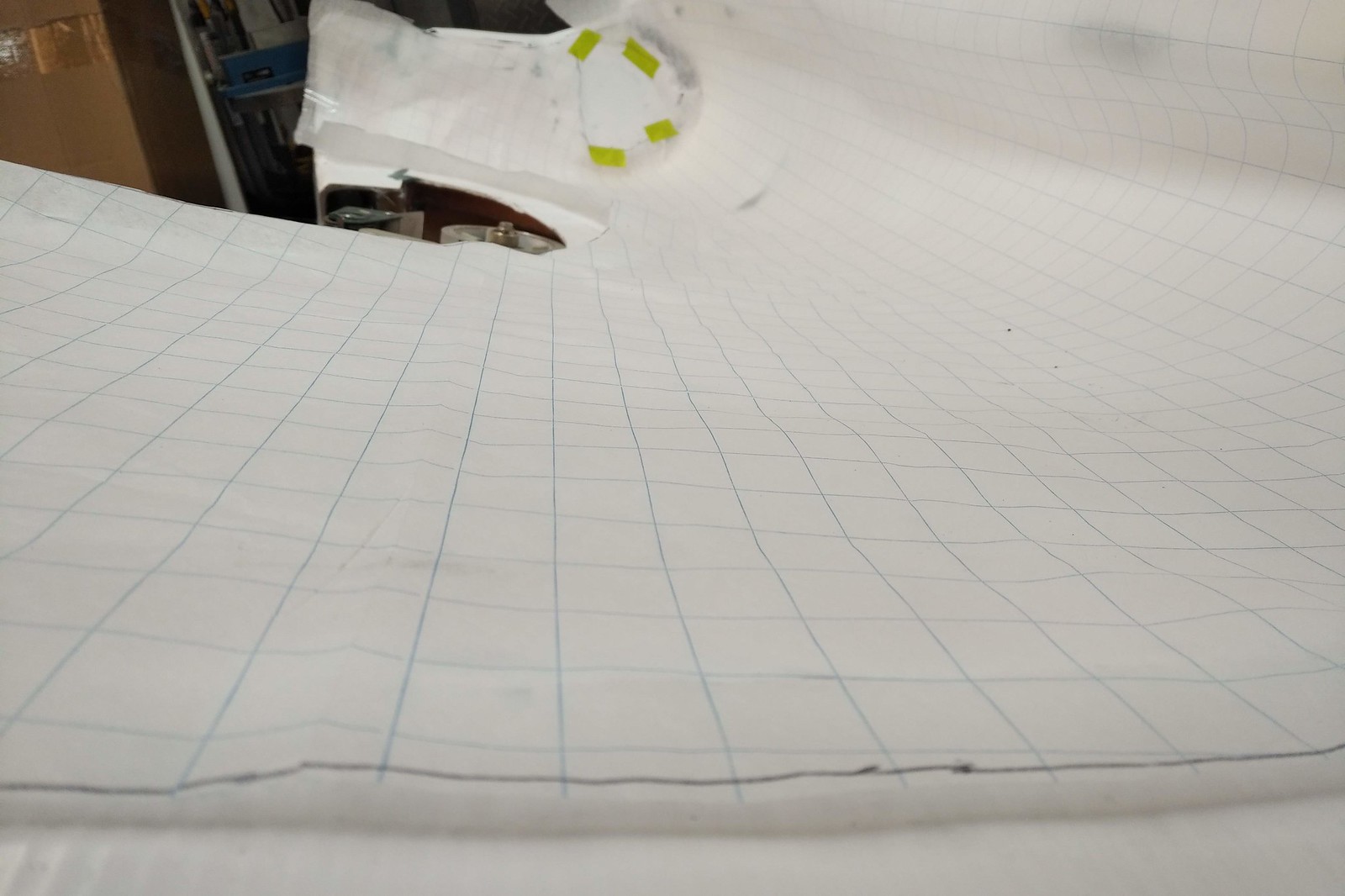

So a few patterns got made...

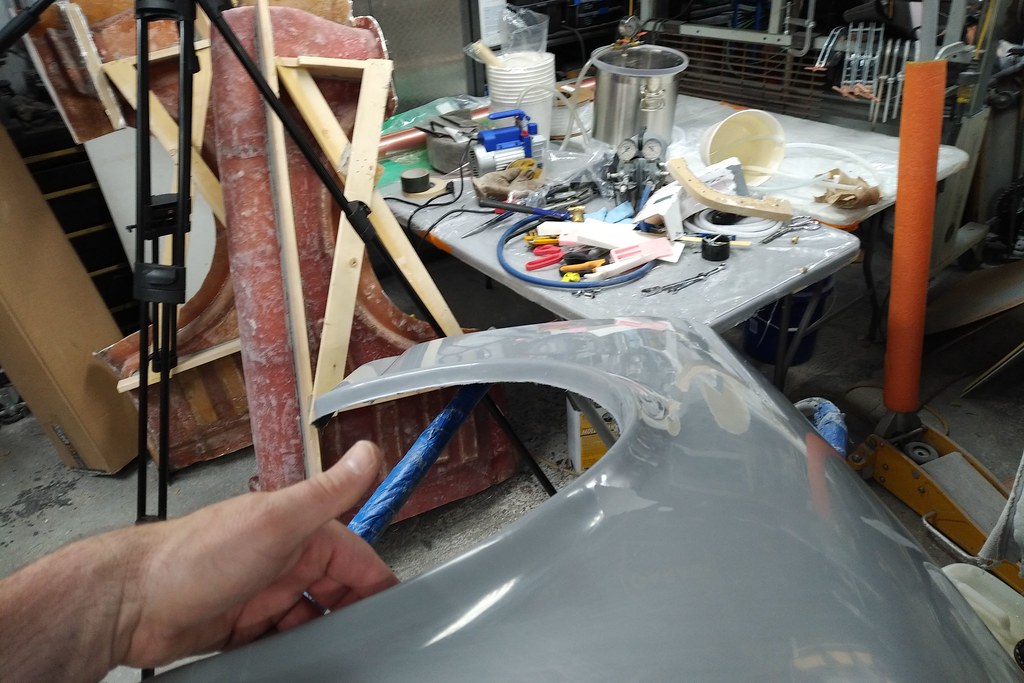

I sprayed a few coats of Duratec VE Primer (with a 2.3 mm fluid tip gun...this stuff is thick) in the mold once the surface was coated with mold release.

It dried nicely. Revealing a few small flaws that I decided I don't care about (just a few pin holes).

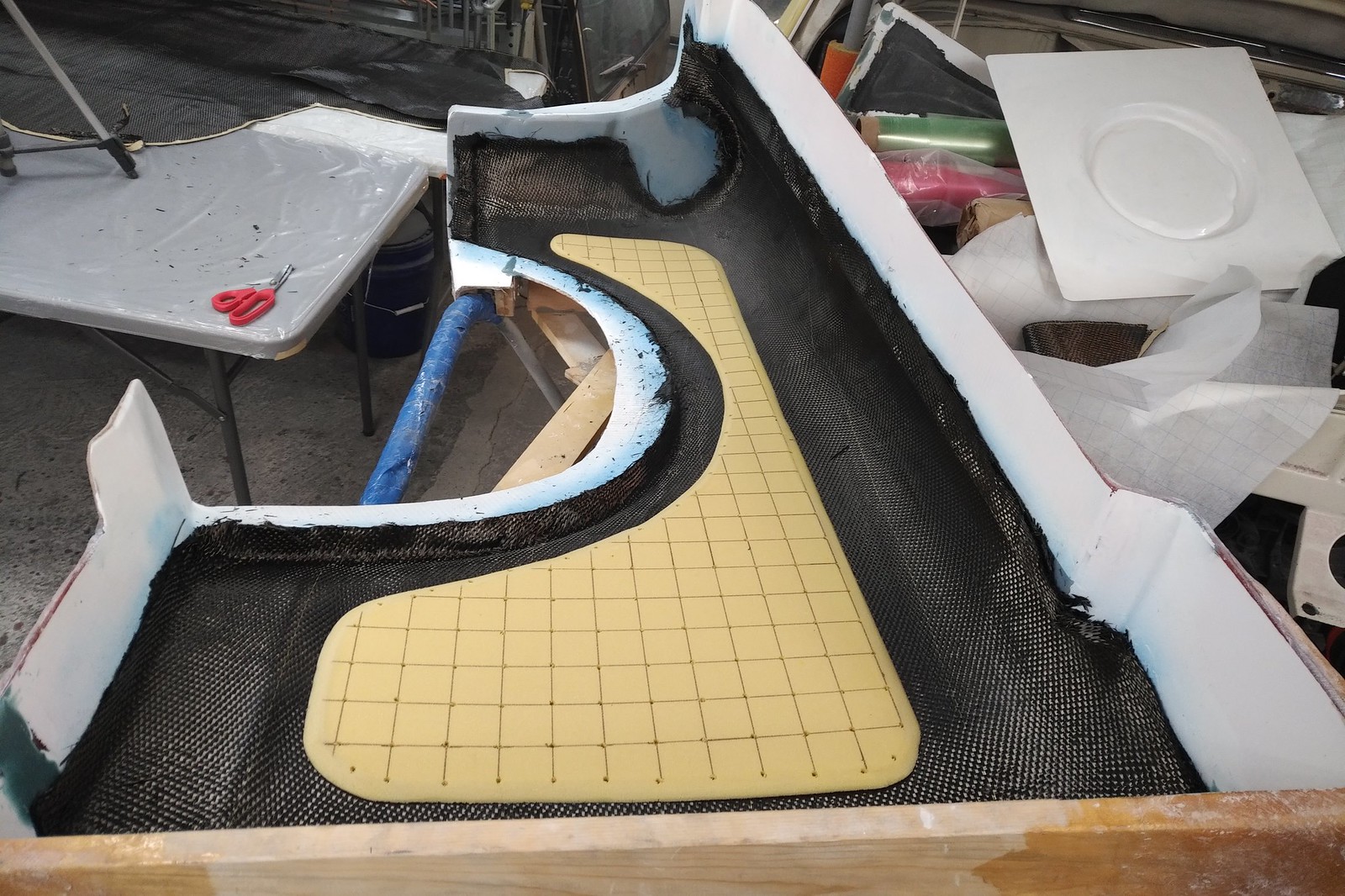

Then it was time to start loading the carbon fabric. I'll try to keep this part sensible - it's harder than it looks to do a fender. Lots of compound curves and flanges and stuff in the way. I'm also down to working in about 2 square metres in my garage.

The fabric is a 6K 369 gsm 5S Harness weave. It's got some good strength properties and drapes nicely, but was shifting a lot, so I'm glad I'm painting this stuff. Twill is far easier to work with.

This layer is laid with the "strength" going along the panel. Next up some 12K 150 gsm ±45° biaxial cloth. It's not woven - and the angles were placed off set to the first layer (so they're going across the panel at ±45°. Make sense?

Then another layer of the harness weave 90° to the first layer. It went in easier than the first.

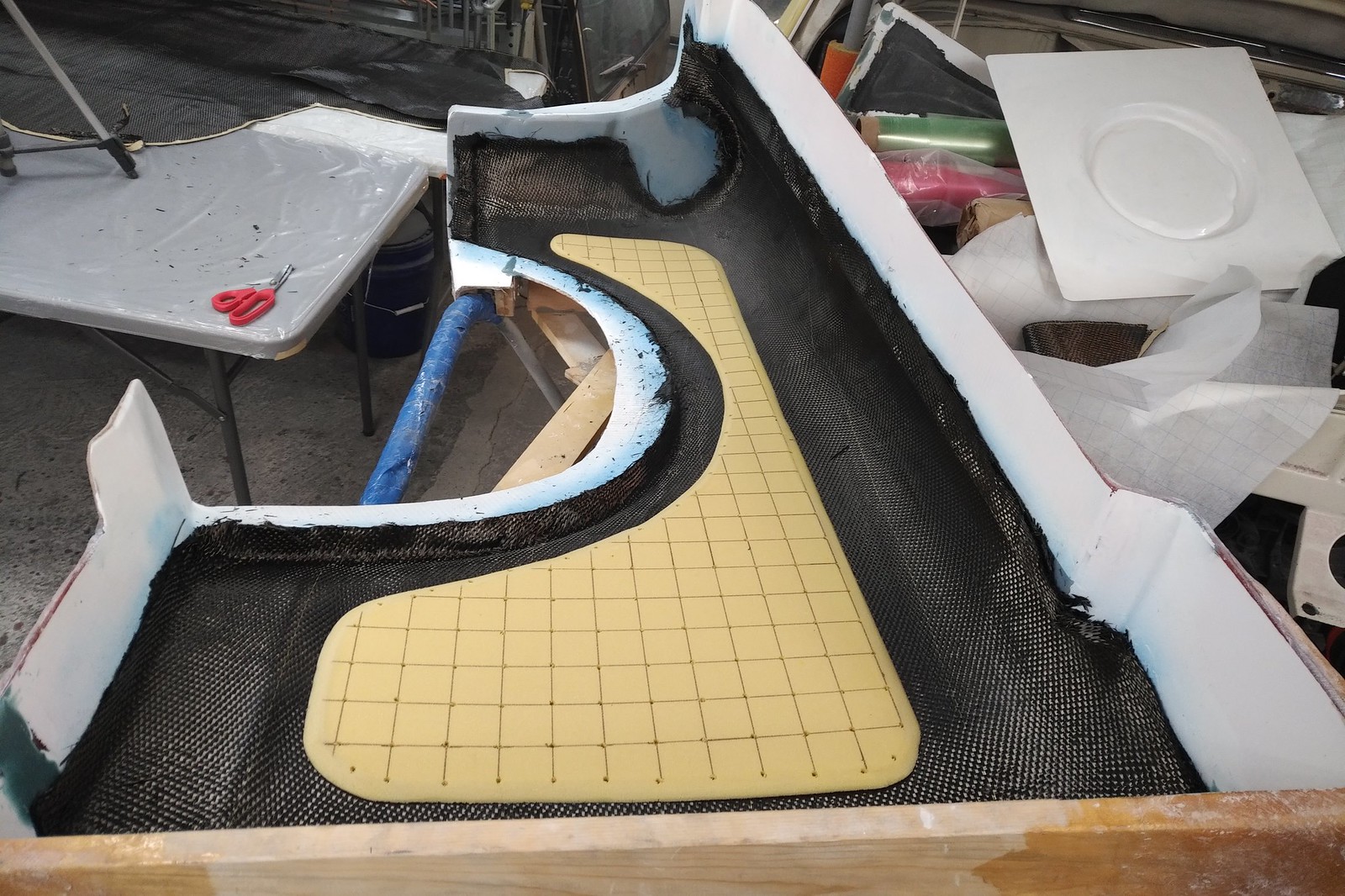

I then added a urethane foam core (mycell) - 6 mm thick with 1/8" holes drilled on a 1.5" grid.

Another layer of the ±45° biaxial cloth over that...we're starting to have some bulk here.

And a final layer of the harness weave.

I'll be bagging this all up later tonight and then infuse it with epoxy later this week. Total weight of the finished part is 1.7 kg of carbon = total around 2.8 kg when done.