I'm going to put this post in here because that's where I think it belongs. I finally got Greg's port work done this weekend. It took me quite a bit longer to do the B20 than my previous B18 work as the casting is much harder (or my bits have gotten duller). I decided to try to capture a few things photographically and measured a few more things to get a sense of the numbers. I'll post the numbers later.

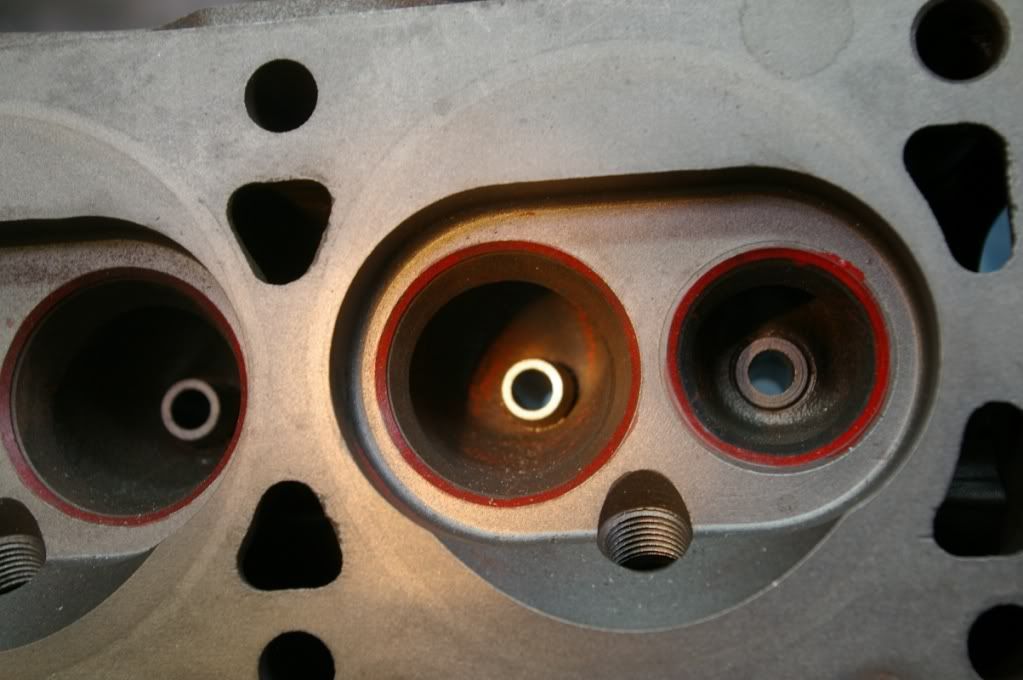

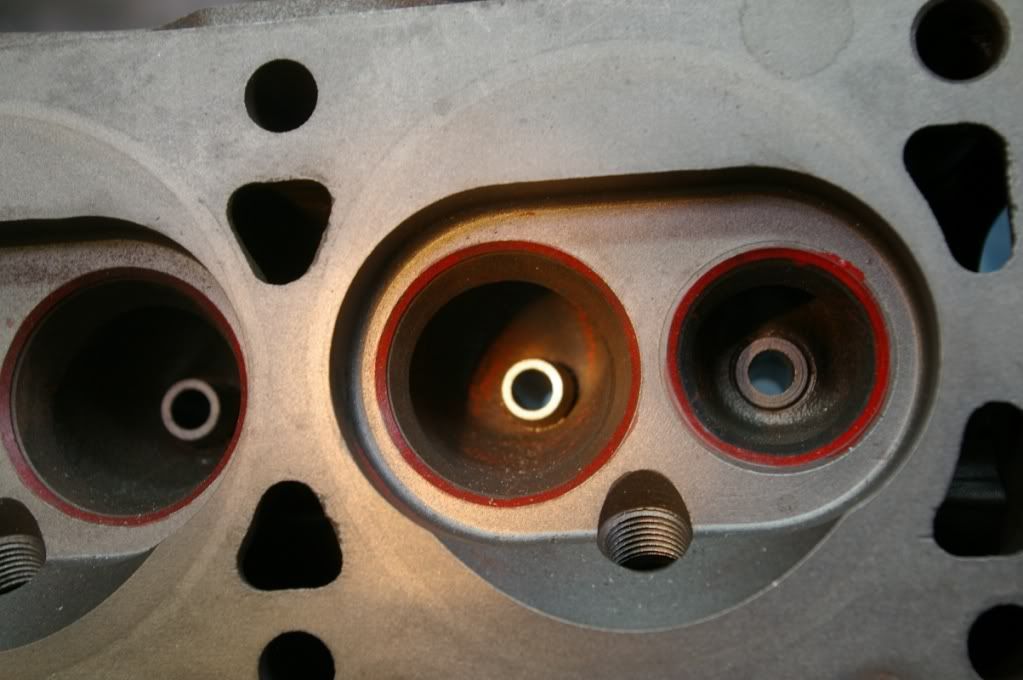

So here we are again at the start - we all know about the valve restriction in these heads - here's how I've captured it digitally. The red lines are my "idiot" lines for porting and keep me away from the seat area.

Face on - sure looks like the normal shot.

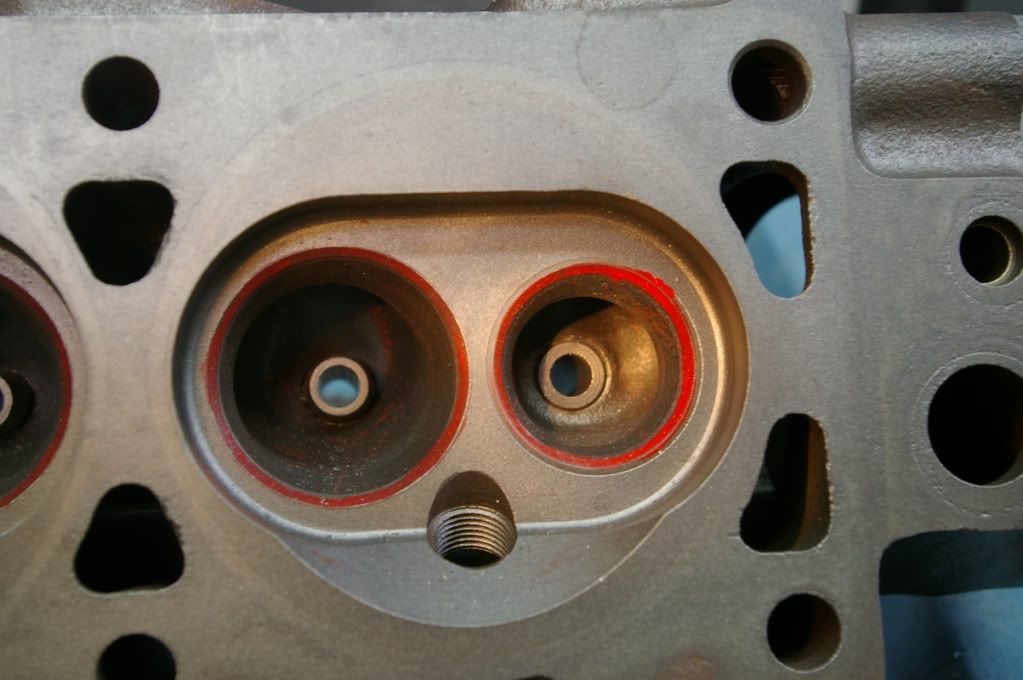

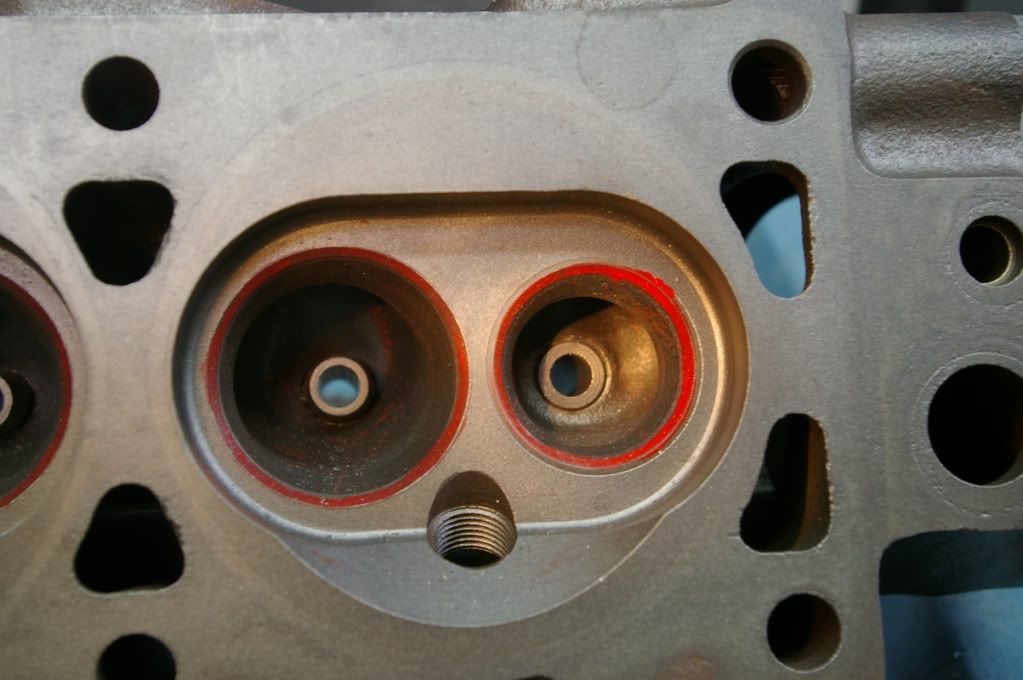

Lets light it a little differently.

Intake...

Exhaust...

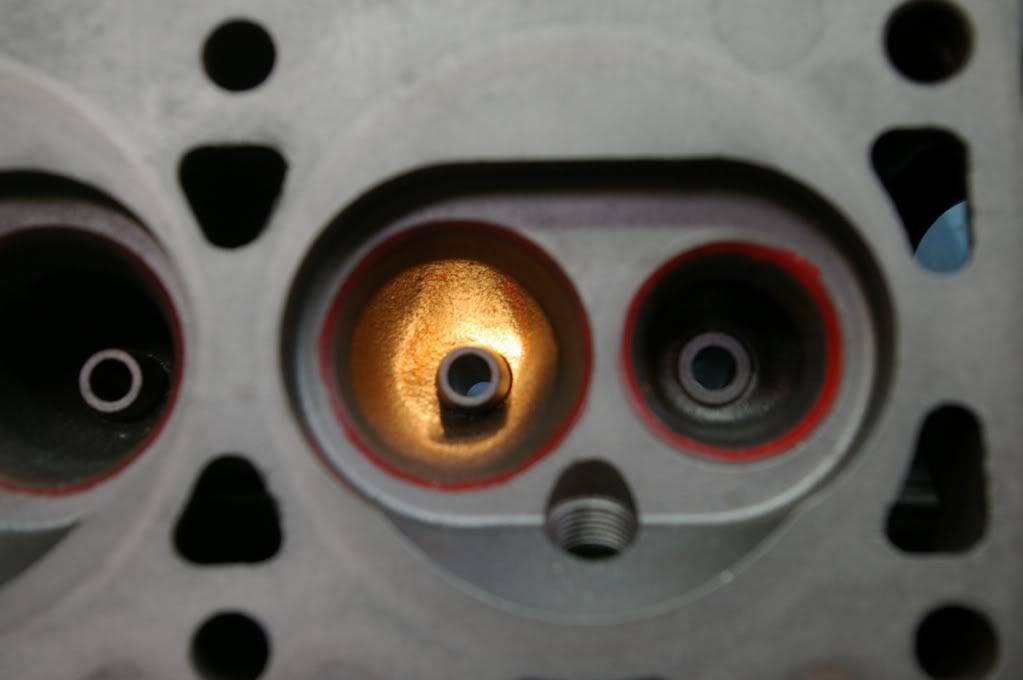

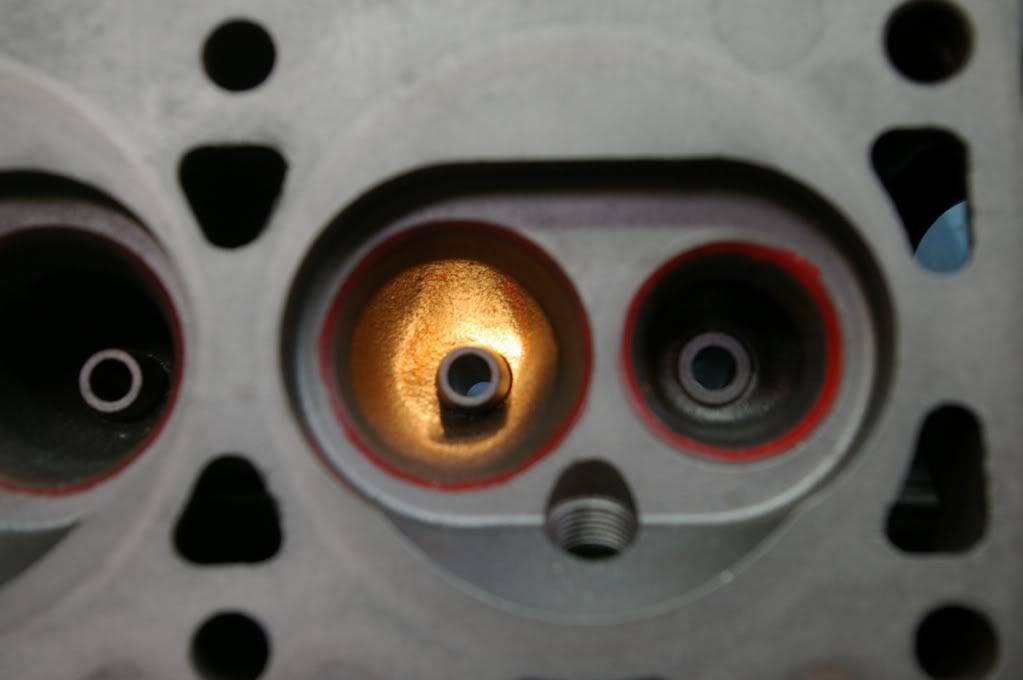

Inside the intake - some attempt has been made to help flow around the valve.

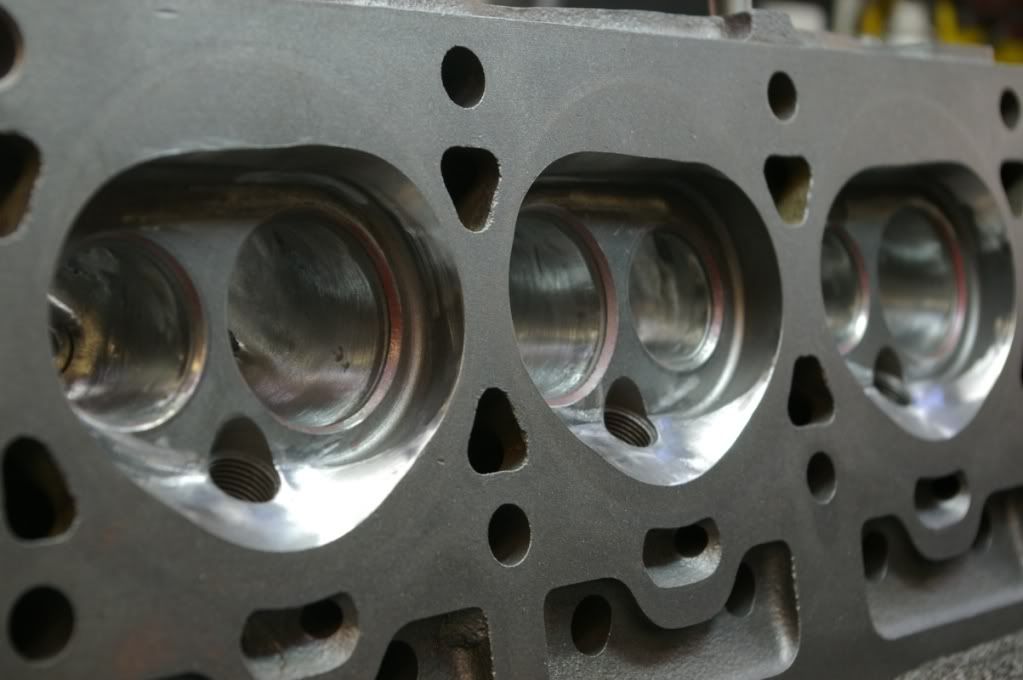

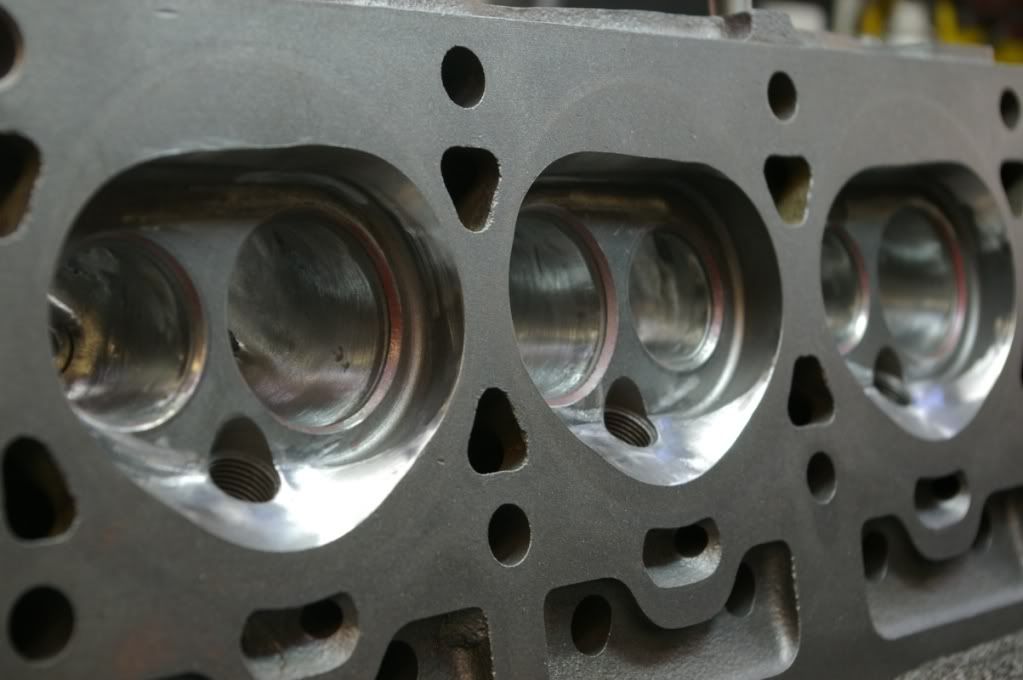

About 6.5 hours of porting later we have this...

I've preserved the port bias and tried to improve things in the intake and exhaust tract. Here you can see how I've opened up the area behind the valve almost to the valve seat.

I've tried to direct the flow a little more forcefully around the intake valve and have done what I can with the exhaust (while preserving it's bias).

Finish on the intakes was left coarse - the exhausts were fine finished, but not polished.

Combustion chamber alteration - I've tried to unshroud the intake vertically here a little and clean up the ramps into the spark plug area.

I've not gone too far - but this is a little further than my B20 head. The good news is that nothing else on Greg's car will change - only the head. So we'll see how things get better as a result of improved compression and the port work.